Protective coating of the brushes of the blades of your factory: how to determine that it is time to conduct service and why is it so important for reliable operation of the fans

2025-03-14

In modern industrial enterprises, ventilation systems play a key role in maintaining safety and optimal working conditions. One of the important components of these systems are fans, in particular, their blades, which are often equipped with protective coating brushes. Despite its apparent insignificance, the protective coating of the brushes of the blades is critical of stable fan operation. It protects the surface of the blades from corrosion, mechanical damage and pollution, which significantly extends the service life of the equipment and reduces operating costs.

In this article, we will consider why it is important to monitor the condition of the protective coating of the brushes of the blades, which signs indicate the need for their maintenance, as well as give practical recommendations for maintenance for this component. We will also discuss how timely maintenance helps to increase the efficiency of the ventilation system and reduce the costs of repair and replacement of equipment.

1. The value of the protective coating of the brushes of the blades

1.1 protective coating functionhttp://www.hengdingfan.ru

The protective coating of the brushes of the blades is designed to protect the surface of the blades from wear, corrosion and the effects of aggressive media. It performs the following functions:

- Corrosion prevention:The protective layer prevents the contact of metal elements with moisture and chemicals, which significantly reduces the risk of corrosion.

- Reduced wear:The protective coating reduces mechanical damage that occurs during friction and vibrations, extending the life of the blades.

- Ensuring stable work:A clean and intact surface of the brushes provides an uniform distribution of air flow and reduces the noise level, which positively affects the efficiency of the fan.

1.2 impact on system performance

The state of protective coating directly affects aerodynamics and, therefore, on the performance of the fan. A worn or damaged coating can lead to:

- Air distribution disorders:Changing the surface of the blades reduces the effectiveness of the creation of the air flow.

- Increase in energy consumption:The fan will be forced to work with increased loads to achieve the required volume of air, which will lead to an increase in energy consumption.

- Increased noise level:An uneven distribution of air flow can cause additional vibrations and noise, which negatively affects the comfort of work.

2. Signs indicating the need to maintain a protective coating

To determine that the protective coating of the brushes requires maintenance, it is necessary to pay attention to the following signs:

2.1 visual inspection

The first step is a regular visual examination of brushes. Pay attention to:

- Wear or attachment of the coating:If the protective layer looks wound or faded, this may indicate the beginning of his wear.

- The presence of cracks and chips:Small cracks, chips, or protective coating, indicate its damage.

- Color change:The presence of spots or color changes can be a sign of corrosion or chemical exposure.

2.2 Change in working parameters

If you notice that the fan has begun to work less efficiently, this may be due to a deterioration in the state of the protective coating. The main features:

- Reducing the volume of moved air:Changes in aerodynamic characteristics may indicate damage to the surface of the blades.

- Increased energy consumption:The fan will consume more energy to achieve previous indicators of work.

- Improving noise and vibration levels:Wondered brushes can cause an uneven distribution of air flow, which leads to increased noise and vibrations.

2.3 Reducing the overall efficiency of the system

If the overall efficiency of the ventilation system has decreased, this may be due to a deterioration in fan operation due to a worn protective coating. Pay attention to:

- Changes in the temperature mode:The inability of the fan to effectively remove heat.

- Air exchange problems:Uneven distribution of air in the room.

3. Recommendations for the maintenance of a protective coating

3.1 Regular checks

Introduce the plan of regular inspections of the state of the protective coating of the brushes of the blades. This will allow timely detection of damage and take restoration measures.

- Examination frequency:It is recommended to conduct a visual inspection at least once a month.

- Using specialized equipment:If necessary, use magnifying devices for a detailed surface analysis.

3.2 Cleaning and repair

In case of minor damage or wear, it should be carried out:

- Surface cleaning:Use soft brushes and neutral detergents to remove dust and pollution.

- Repair of a protective layer:When identifying small cracks or chips, it is advisable to carry out repair work using recovery compositions suitable for this material.

3.3 Preventive maintenance

Preventive maintenance includes not only regular cleaning, but also replacing worn components:

- Replacing brushes:If damage to the protective coating exceed the permissible norms, the brushes should be replaced with new ones.

- Protective layer update:In some cases, it is possible to apply an additional protective coating, which extends the life of the blades.

3.4 staff training

Qualified personnel plays a key role in maintaining the optimal state of equipment. Regular training in maintenance and use of specialized equipment for checking the protective coating will help:

- Timely identify problems.

- Conduct quality maintenance.

- Reduce the risk of emergency situations due to fan malfunctions.

4. The use of radial centrifugal fans with optimal maintenancehttp://www.hengdingfan.ru

4.1 Industrial use

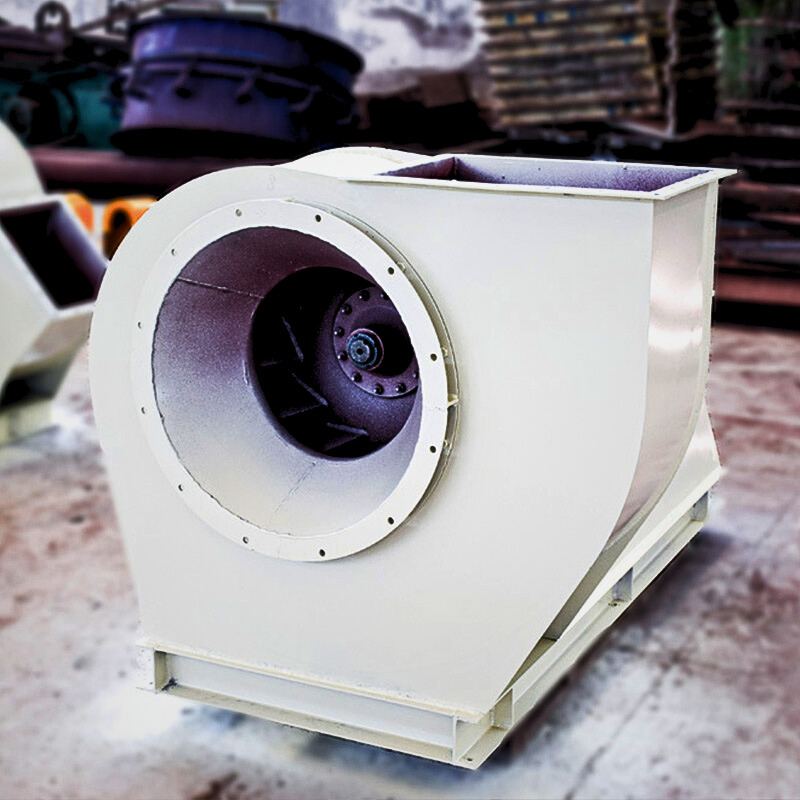

Radial centrifugal fans are widely used in industrial ventilation systems for cooling equipment and providing air exchange. Regular maintenance of the protective coating of the brushes of the blades allows:

- Maintain optimal performance.

- Reduce energy consumption.

- Increase the life of the equipment.

4.2 ventilation of mines and mines

In the mining industry, reliable ventilation is critical for safety. The damaged protective coating of the brushes of the blades can lead to a decrease in the efficiency of the fan, which in turn increases the risk of explosive gases. Preventive maintenance and timely replacement of brushes help to ensure stable air exchange and safety at the mine.

4.3 Application in commercial facilities

In shopping centers and office buildings, the noise level and energy efficiency are of great importance. The optimal condition of the protective coating of the brushes of the blades contributes to:

- Decreasing noise level.

- Increasing the energy efficiency of the system.

- Creating a comfortable microclimate for visitors and employees.

5. Examples of successful projects

5.1 Example from an industrial plant in Russia

At one of the large factories in Russia, regular maintenance of the ventilation system was carried out, including checking the protective coating of the brushes of the blades. Thanks to the timely cleaning and repair of brushes, it was possible to maintain optimal fan performance, which led to a decrease in energy cost by 12% and an increase in the service life of the equipment. This example demonstrates how even small details can significantly affect the effectiveness of the entire system.

5.2 An example from a mine in Kazakhstan

In one of the mines of Kazakhstan, a system of regular maintenance of ventilation equipment was introduced. Particular attention was paid to the state of the protective coating of the brushes of the blades. Due to this, the risk of malfunctions was significantly reduced, and the ventilation efficiency was stably maintained at a high level. This contributed to an increase in the safety of the mine and a decrease in repair costs.

5.3 An example from a shopping center in Europe

In one of the shopping centers in Europe, to increase energy efficiency and reduce noise, the ventilation system was modernized. Regular verification and maintenance of the protective coating of the brushes of the blades made it possible to create comfortable conditions for visitors and reduce operating costs. Optimization of the work of equipment has led to an increase in energy efficiency by 10% and a significant decrease in noise level in the building.

6. Recommendations for optimizing the service of protective coating of the brushes of bladeshttp://www.hengdingfan.ru

6.1 Organization of regular inspections

Introduce the system of scheduled inspections in order to timely detect signs of depreciation wear. This will avoid large breakdowns and reduce the risk of emergency situations.

6.2 Using modern diagnostic tools

Use special devices for visual and instrumental monitoring of the condition of the brushes of the blades. This may include the use of magnifying devices, photo documentation and software for analyzing the condition of equipment.

6.3 training and advanced training of personnel

Technical personnel training methods for diagnosing and servicing ventilation equipment will help to significantly reduce the risk of error in operation. Regular trainings and seminars contribute to increasing the efficiency of maintenance and extending the service life of equipment.

6.4 Implementation of innovative technologies

Modern technologies, such as intellectual monitoring systems and automation of service processes, allow you to monitor the state of protective coating in real time and respond promptly to changes. This helps maintain the optimal condition of the equipment and reduce operating costs.

7. Conclusionhttp://www.hengdingfan.ru

The protective coating of the brushes of the fan blades is an important, but often an inconspicuous element, on which the efficiency and reliability of the ventilation system directly depends. Timely maintenance and regular checks allow you to maintain it in optimal condition, reducing energy consumption, increasing productivity and increasing the service life of the equipment.

Examples of successful projects demonstrate that even small parts can significantly affect the operation of ventilation systems. The introduction of monitoring systems, the use of modern diagnostic tools and professional training of staff - all this contributes to the creation of an effective and reliable ventilation system.

Choose high -quality equipment from trusted suppliers and do not neglect regular maintenance to ensure long -term stable operation of ventilation systems and create safe working conditions for all employees of the enterprise.