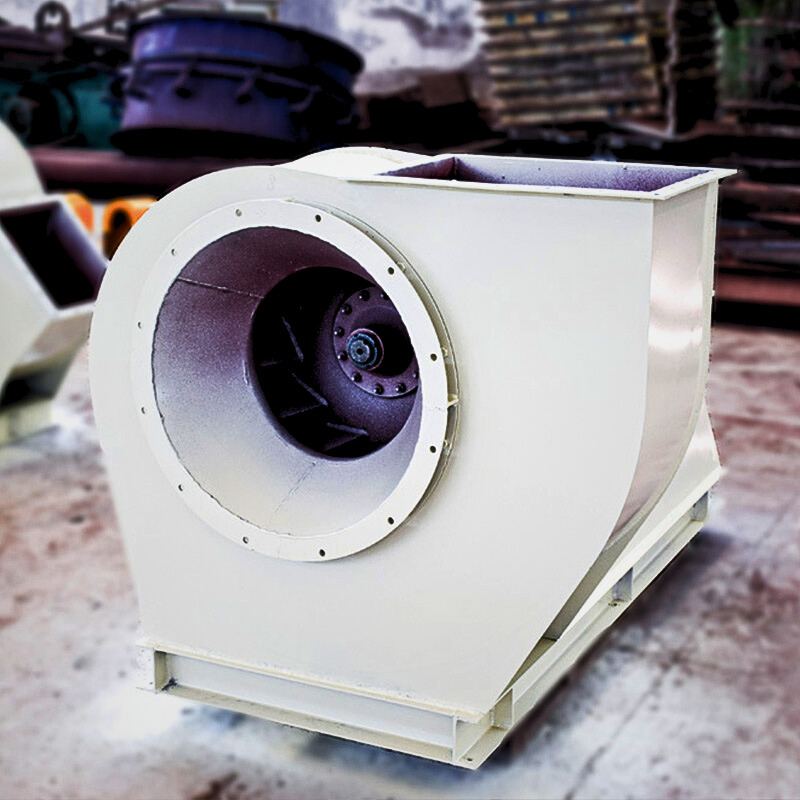

10 ordered FBD10 2 × 75 kW fans: ready to be sent to Serbia to modernize industrial infrastructure

2025-03-12

In the context of the rapid development of industry and the globalization of production, high -quality ventilation equipment becomes a strategically important element of ensuring stable operation of objects. Recently, our company successfully completed the order for 10 fans of the FBD10 2x75 kW models, which are already in the warehouse and are ready to be sent to Serbia. This order is a significant step towards the modernization of ventilation systems to improve energy efficiency, increase productivity and ensure safety at industrial facilities.

In this article, we will talk in detail about the technical characteristics of the FBD10 2x75 kW fans, the value of this order for the Serbian market, and also consider the process of preparing, checking and sending equipment. We will pay special attention to how high -performance fans help to improve the operation of ventilation systems, which in turn has a positive effect on the overall efficiency of production processes. http://www.hengdingfan.ru

1. Technical characteristics of fbd10 2x75 kW fans

1.1 power and performance

FBD10 fans equipped with powerful 2x75 kW electric motors are designed to work in high load conditions. Such power allows you to ensure a stable and significant volume of air flow, which is critical for ventilation systems at large industrial facilities. High power guarantees that even with long pipelines and significant static pressure, the equipment will be able to work effectively, providing optimal air exchange.

1.2 rotation speed and aerodynamics

At a rotation speed of about 2900 rpm, FBD10 fans demonstrate excellent aerodynamic characteristics. This allows you to create a powerful flow of air, which is evenly distributed throughout the ventilation system. The correct combination of speed and the design of the blades minimizes turbulence and reduces energy consumption, which makes the equipment energy -efficient.

1.3 Diameter of the air duct and flow parameters

Depending on the configuration of the system, FBD10 fans are designed to work with various diameters of the ducts, which allows for the required volume of the air flow. The volume of air measured in m³/min varies depending on the specific model and operating conditions, which makes it possible to choose the optimal solution for a particular object.

1.4 Protection and reliability

Particular attention in the design of the FBD10 fans is paid to equipment protection. IP55 class protection guarantees that fans are resistant to dust and water jets, which is especially important for working in aggressive conditions. Additionally, the isolation class H provides reliable operation of electric motors at high temperatures, which significantly extends the service life of the equipment.

2. The use of fbd10 2x75 kW fans

2.1 Industrial cooling and ventilation

At large industrial enterprises, ventilation is a key element for maintaining the optimal temperature regime and production safety. Fabd10 2x75 kW fans are used to cool production lines, excess heat and ensure stable air exchange. This contributes not only to reducing the risk of equipment overheating, but also to increase the overall productivity of the plant.

2.2 ventilation of mines and underground structures

In mines and mines, stable ventilation is of paramount importance for staff safety. Due to the high performance and reliable protection (IP55, the isolation class H), the FBD10 fans are successfully used to ensure the flow of fresh air, remove harmful gases and dust, which reduces the risk of emergency situations and increases the safety of miners.

2.3 commercial and office buildings

Effective ventilation in shopping centers, office buildings and other commercial facilities provides comfort for employees and visitors. In such objects, not only performance and energy efficiency are important, but also a low noise level. The FBD10 fans, thanks to an optimized design, allow you to create a favorable microclimate, reducing the noise and energy consumption.

2.4 transport systems and tunnels

Ventilation systems in tunnels and transport corridors require equipment that can work in high loads and long pipelines. FBD10 fans demonstrate excellent indicators for overcoming static pressure, which allows for a constant influx of fresh air and safe conditions for passengers and personnel of transport systems.

3. Stages of preparation of the order and its significance

3.1 Collection and preparation of the order

An order from 10 fbd10 fans 2x75 kW has already been assembled and is in a warehouse. Each fan has passed strict quality control, including checking all technical parameters: performance, working pressure, rotation speed, as well as IP55 protection level and IP55 and insulation class H. Such an integrated approach ensures that the equipment meets all the customer requirements and is ready for operation under difficult conditions.

3.2 Logistics and delivery

After completing the assembly and quality check, the equipment was prepared for sending. The company's logistics service organizes the transportation of the order to Serbia, which is an important stage in international cooperation. Timely delivery guarantees that the fans will be installed and launched in the work as soon as possible, which will positively affect the optimization of the ventilation system at the customer facility.

3.3 of the order for the market

The order for 10 FBD10 fans 2x75 kW indicates high demand for modern ventilation equipment in the international market. Sending an order to Serbia emphasizes the importance of using high -tech solutions to modernize ventilation systems in countries with a developing industry. This is also an example of successful international cooperation aimed at increasing energy efficiency and safety of production processes.

4. Practical recommendations for choosing ventilation equipment

4.1 Analysis of operating conditions

Before choosing a fan, it is necessary to conduct a detailed analysis of the conditions in which the ventilation system will work. It is important to consider:

- The size of the room and the length of the pipelines.

- The required volume of air (m³/min) and static pressure (PA).

- Environmental features (temperature, humidity, the presence of dust and aggressive chemicals).

4.2 Careful calculation of parameters

Conducting calculations is the basis for the correct selection of equipment. The exact calculations of the volume of air, pressure and energy consumption will allow you to choose a fan that will ensure the optimal operation of the system at minimal energy costs.

4.3 Choosing reliable equipment

When choosing a fan, give preference to proven models from reliable manufacturers, which can ensure high quality, durability and energy efficiency. Particular attention should be paid to parameters such as the IP55 protection and the isolation class H, guaranteeing the stability of the equipment in difficult operating conditions.

4.4 installation and integration

The correct installation of ventilation equipment is the key to its long -term operation. Recommended:

- Accurate alignment of equipment with a duct system.

- The use of high -quality fasteners and sealants to prevent air leaks.

- Integration with modern monitoring systems that allow you to control the parameters of work in real time.

4.5 Service and technical control

Regular maintenance and preventive measures will help maintain the optimal working characteristics of the fan, reducing the risk of breakdowns and reducing operational costs. Planned service includes:

- Cleaning filters and air ducts.

- Checking and lubrication of bearings.

- Regular monitoring of equipment using sensors and automatic control systems.

5. Examples of successful projects

5.1 Industrial enterprise in Russia

At one of the large factories in Russia, a ventilation system was introduced using radial centrifugal fans FBD10 2x75 kW, calculated taking into account long pipelines. Due to the exact calculation of the parameters and professional installation, it was possible to increase the volume of the moving air by 25% and reduce energy consumption by 18%. This increased productivity and ensured the safety of production.

5.2 Mine in Kazakhstan

In one of the mines of Kazakhstan, the installation of modern FBD10 fans made it possible to provide stable ventilation even in conditions of long and winding pipelines. Optimization of the ventilation system reduced the risk of explosive gases, which significantly increased the safety of workers and reduced operational costs.

5.3 shopping center in Europe

In one of the large shopping centers in Europe, the ventilation system using fbd10 2x75 kW fans was modernized. Thanks to integration with automatic control systems and the exact selection of equipment parameters, it was possible to create an uniform air flow, reduce the noise level and reduce energy consumption. This led to a significant improvement in the microclimate in the building and reduce operating costs.

6. Economic efficiency

6.1 Reduction of electricity costs

An optimized ventilation system can significantly reduce electricity consumption. Highly effective fans, correctly selected in parameters, allow reducing energy consumption, which positively affects the financial indicators of the enterprise.

6.2 Improving safety and performance

Effective ventilation reduces the risk of emergency situations associated with the accumulation of harmful gases and dust, which ensures security of employees and increases the productivity of the enterprise. A reliable ventilation system helps to avoid downtime of equipment and reduces repair costs.

6.3 Return of investment

Investments in high -quality ventilation equipment are paid off by reducing operating costs, increasing the service life of equipment and increasing overall performance. Long -term operation of the optimized ventilation system contributes to a significant savings in the funds and improve the financial indicators of the enterprise.

7. Conclusion http://www.hengdingfan.ru

The choice of a suitable radial centrifugal fan, taking into account all the technical parameters and features of the pipeline system, is a key factor for ensuring effective, safe and economical operation of the ventilation system. A thorough analysis of operating conditions, accurate calculation of the necessary parameters and the choice of reliable equipment with the protection of IP55 and the insulation class H allow to achieve significant energy savings, increasing productivity and ensuring safety at the facility.

Real examples of successful projects from Russia, Kazakhstan and Europe demonstrate that competent design and optimization of the ventilation system pay off by reducing energy consumption and increasing the overall efficiency of the enterprise. The integration of modern monitoring systems, automation of processes and regular maintenance - all this contributes to the long -term stability of the operation of ventilation systems and a decrease in operating costs.

Choose equipment from trusted manufacturers and attract qualified specialists for calculations, installation and maintenance. Such an integrated approach will ensure the maximum return on investment and will allow your company to work with minimal costs and maximum efficiency for many years.