In three minutes: how does the explosion -proof fan work? Key points for ensuring the explosion of the fans

2025-03-12

In conditions where explosive gases and dust are present, ensuring the safety of equipment becomes a priority task. Explosion -proof fans are a specialized equipment designed to work in dangerous environments, where the risk of fire and explosion is especially high. This article will help you quickly figure out how an explosion -proof fan works, what technologies and standards are used to protect it, and why the correct choice and maintenance of such devices is critical for the safety and efficiency of industrial facilities. http://www.hengdingfan.ru

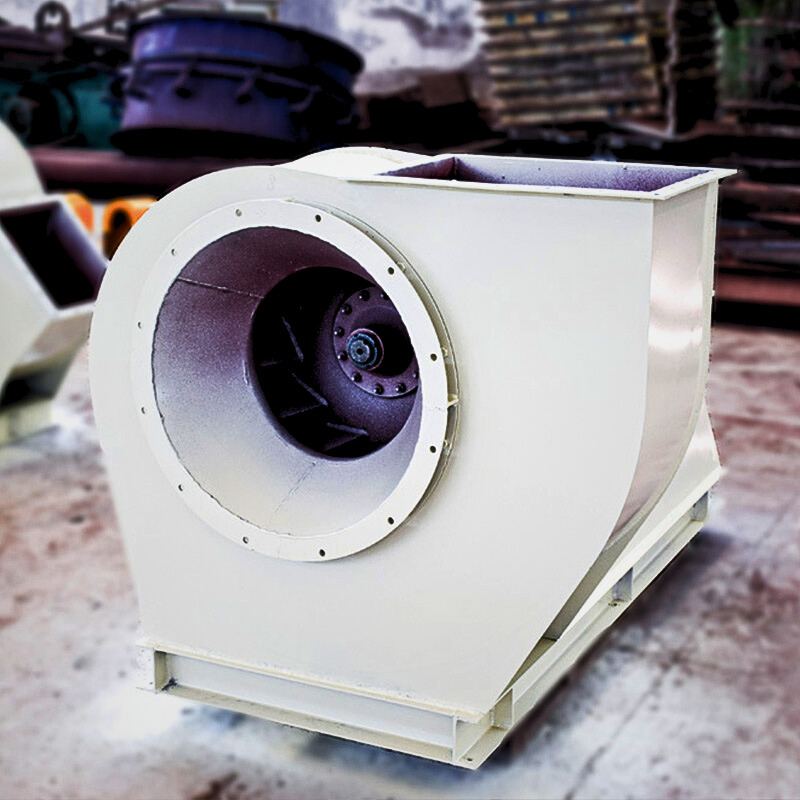

1. What is itExplosion -proof fan?

1.1 Definition and necessity

An explosion -proof fan is a device designed to work in conditions where there are explosive gases or dust mixtures. Such devices are designed in such a way as to prevent sparks or high temperatures that can ignite the environment. Their use is extremely important in sectors such as a chemical, petrochemical, mining industry, as well as at objects where flammable materials are used.

1.2 The main tasks

The main task of the explosion -proof fan is to ensure safe air circulation, which includes:

- Removing harmful and explosive gases.

- Maintaining the optimal level of oxygen.

- Reducing the risk of fires and explosions.

- Creating a favorable microclimate for workers and equipment.

2. Principles of ensuring explosion protection

2.1 Design features

So that the fan can work in an explosive environment, its design must meet a number of requirements:

- Isolated design:All elements that can become a source of sparking or overheating should be reliably isolated from the environment.

- Using special materials:The use of materials resistant to aggressive media, high temperatures and corrosion plays an important role in the durability of equipment.

- Theater optimization:To prevent overheating, cooling systems and special heat excess elements are used.

2.2 Security standards

Explosion -proof equipment must comply with international and national security standards. The most common standards:

- ATEX (Atmosphères Explosibles):The European standard that determines the requirements for equipment used in potentially explosive zones.

- Iecex:The international standard that regulates technical requirements for explosion -proof equipment.

- GOST and other national standards:Different countries have their own standards, which must also be taken into account when choosing equipment.

These standards determine which categories of equipment can be used in certain risk zones, as well as the requirements for the design, materials and protection methods.

2.3 Methods of protection

There are several main protection methods used in the design of explosion -proof fans:

- Isolation (ex D):The design that prevents the spread of sparks and heat beyond the device.

- Increased security (ex E):Measures that reduce the likelihood of sparks during normal operation.

- The principle of internal security (ex IA, ex IB):Limiting the energy level of the device so that it cannot cause an explosive mixture fire.

3. Technical aspects of choosing an explosion -proof fan

3.1 power and performance

One of the key parameters is the power of the electric motor, measured in kilowatts (kW). Power determines how much air the device can move, which is critical for systems where high air exchange is needed. It is important to consider that a powerful engine can consume more energy, so the optimal power ratio and performance becomes a key to energy efficiency.

3.2 rotation speed

The rotation speed, measured in a r/min (R/min), affects the dynamics of the air flow. Higher speed contributes to the creation of a strong air flow, but can lead to an increased level of noise and energy consumption. The optimal value should be selected taking into account the requirements of a particular object and characteristics of the pipeline system.

3.3 diameter of the duct and air volume

The diameter of the duct affects the volume of the moving air (Q, m³/min). The larger the diameter, the higher the performance of the fan can be, however, it also affects the static pressure, which should be overcome by the device. Accurate calculations are necessary for the selection of optimal equipment.

3.4 Protection and class of insulation

To work in explosive average conditions, indicators such as IP protection (for example, IP55) and the isolation class (for example, class H) are extremely important. IP55 protection guarantees that the fan is resistant to dust penetration and the effects of water jets, and the isolation class H provides reliable operation of the electric motor at high temperatures.

4. The use of radial centrifugal fans in industry http://www.hengdingfan.ru

4.1 ventilation of mines and mines

In the mining industry, stable ventilation is of paramount importance for safety. Radial centrifugal fans equipped with explosion -proof components provide:

- Effective removal of explosive gases.

- Maintaining the optimal level of oxygen.

- Reducing the risk of accidents and increasing the safety of miners.

4.2 industrial cooling

At industrial enterprises, radial fans are used to cool equipment and industrial premises. Effective removal of hot air helps to prevent overheating of the machines and reduce the likelihood of failures, which directly affects performance.

4.3 Ventilation of transport systems

In metro systems, tunnels and railway communications, it is important to ensure quick and stable air exchange to prevent the accumulation of smoke and harmful gases. Explosion -proof fan fans operating on the principle of centrifugal effect play a key role in maintaining safety and comfort at transport infrastructure facilities.

4.4 Application in trade and office buildings

In large commercial and office buildings, the provision of high -quality ventilation helps to maintain a comfortable microclimate and reduce operational costs. Explosion -proof fan fans with high energy efficiency provide uniform air distribution and minimize the noise level, which is especially important for such objects.

5. Practical recommendations for choosing an explosion -proof fan http://www.hengdingfan.ru

5.1 Analysis of operating conditions

Before choosing equipment, conduct a detailed analysis of the working conditions:

- Study the characteristics of the object: dimensions, pipe configuration, type and concentration of hazardous gases.

- Calculate the required volume of air and static pressure.

- Determine the requirements for protection, including IP protection and isolation class.

5.2 Choosing equipment according to technical parameters

Based on the analysis, choose a fan with optimal technical characteristics:

- Power:Must correspond to the volume of air and working pressure.

- Rotation speed:Optimal for creating a stable flow with minimal energy losses.

- Diameter of the air duct:Corresponding to the parameters of the system.

- IP55 protection and isolation class h:Guaranteed reliable work in aggressive and explosive conditions.

5.3 installation and integration of the system

The correct installation of equipment is crucial:

- Provide the accurate alignment of the fan with the pipeline system.

- Use high -quality fasteners and ensure the tightness of the compounds.

- Integrate the system with modern monitoring tools in order to track the parameters of work in real time.

5.4 maintenance

Regular maintenance will help extend the service life of the equipment:

- Carry out planned examinations and cleaning of fans, filters and ducts.

- Control the condition of electric motors and bearings.

- Update control systems and make monitoring data adjustments.

6. Examples of successful projects

6.1 Example from Russia

On one of the large mines in Russia, a ventilation system was introduced using radial centrifugal fans calculated taking into account long pipelines and high protection requirements (IP55, isolation class H). Due to the optimization of the parameters and professional installation, the volume of the displaced air increased by 25%, and the energy consumption decreased by 18%. This made it possible to increase the safety of the mine and improve the working conditions of the miners.

6.2 Example from Kazakhstan

In one of the mines of Kazakhstan, the installation of modern ventilation equipment with radial centrifugal fans provided a stable supply of fresh air in the conditions of long and winding pipelines. The introduction of a monitoring system made it possible to timely detect deviations in the work, which significantly reduced the risk of explosive gases and increased the overall energy efficiency of the system.

6.3 Example from Europe

In one of the large shopping centers in Europe, the ventilation system was optimized, including the use of energy -efficient radial centrifugal fans with IP55 protection and the IP55 protection class and the thorough calculation of the parameters and the proper installation of the equipment have reduced the noise level, improve the distribution of air and significantly reduce the cost of electricity, which led to increased comfort for visitors and to increase the comfort of visitors and building employees.

7. Economic efficiency and long -term benefits

7.1 Reduction of electricity costs

Optimally selected ventilation systems can significantly reduce energy consumption by reducing pressure losses and increasing the efficiency of electric motors. Energy efficient equipment is paid off by reducing operating costs and reducing downtime.

7.2 Improving safety and reliability

Effective ventilation helps to remove explosive gases and maintain an optimal microclimate, which is critical for the safety of workers at the facility. Reliable equipment that meets protection standards provides long -term stability of the system.

7.3 Increase in the life of the equipment

Regular maintenance and the use of quality components, including IP55 protection and isolation class H, significantly extend the service life of ventilation equipment. This reduces the costs of repairing and replacing parts, which positively affects the overall economic efficiency of the enterprise.

8. Recommendations for implementation http://www.hengdingfan.ru

8.1 detailed analysis of the conditions of the object

Before choosing the equipment, it is necessary to conduct a comprehensive analysis of the characteristics of the object, including the size of the premises, the length and configuration of pipelines, the level of pollution and the requirements for air exchange. This will allow you to choose the optimal models of the fans and configure the system to achieve maximum efficiency.

8.2 Cooperation with trusted suppliers

The choice of equipment for reliable manufacturers with confirmed certificates and positive reviews guarantees high quality and reliability of the ventilation system. It is recommended to compare technical characteristics and take into account the experience of previous projects.

8.3 Integration of modern control systems

Modern monitoring and automatic control systems allow in real time to control the fan settings. This provides operational response to changes in conditions and allows for preventive maintenance, reducing the risk of accidents and increasing the energy efficiency of the system.

8.4 Training and advanced training of personnel

Qualified personnel are the key to the successful operation of the ventilation system. Regular training of specialists in the operation and maintenance of equipment will help reduce the number of errors and increase the overall efficiency of the system.

9. Conclusion http://www.hengdingfan.ru

The choice of the optimal radial centrifugal fan, taking into account the length of the pipeline system, technical parameters and operating conditions, is a key factor for creating an effective, reliable and economical ventilation system. A detailed analysis of conditions, accurate calculations and competent implementation of modern technologies can reduce electricity costs, increase the safety and durability of equipment, as well as ensure comfortable working conditions at the facility.

Practical examples from Russia, Kazakhstan and Europe demonstrate that an integrated approach to the selection and installation of ventilation equipment is paid off by increasing productivity and reducing operating costs. Cooperation with trusted suppliers, the integration of monitoring systems and regular maintenance are the key to the successful operation of ventilation systems.

Investments in high -quality equipment and competent management of ventilation systems not only increase the efficiency of the enterprise, but also contribute to significant savings in funds, ensuring long -term stability and safety.