How to choose a suitable model of the axial fan depending on the scale of your plant: practical recommendations and key factors to save money

2025-03-14

Effective ventilation is an integral part of modern industry, ensuring safety, optimal working conditions and stable cooling of equipment. Ospass fans are one of the most common solutions for creating air exchange systems. However, the choice of the correct model of the axial fan depends on many factors, among which the key is the scale of your plant. Not only the quality of air exchange depends on the correct selection of equipment, but also energy saving, reducing operation costs and increasing productivity.http://www.hengdingfan.ru

In this article, we will consider in detail how to choose a suitable model of the axial fan, taking into account the size of the plant. We will discuss the main technical parameters that need to be taken into account, consider examples of calculations and give practical recommendations for optimizing the ventilation system. In addition, we will pay attention to issues of energy efficiency, reducing operational costs and ensuring the reliability of the operation of ventilation equipment.

1.The role of axial fans in industrial ventilation

Ospass fans are designed to move air along the rotation axis. Due to their design, they are able to provide a large volume of air with a relatively low pressure drop. This makes them ideal for use at enterprises with large production facilities, warehouses, workshops and factories, where constant air exchange is required.

The main functions of axial fans:

- Providing the influx of fresh air:To maintain the optimal level of oxygen and prevent accumulation of harmful substances.

- Equipment cooling:Effective cooling prevents overheating of machines and increases their service life.

- Removing polluted air:The removal of dust, smoke and chemical vapors to create safe working conditions.

- Creating the optimal microclimate:Regulation of temperature and humidity in industrial premises.

2. The influence of the plant’s scale on the choice of a fan

2.1 Determining the scale of production

Before choosing an axial fan, it is necessary to estimate the scale of your plant. This includes:

- Production room area:The larger the area, the more air exchange is required.

- The volume of air required for ventilation:It is calculated based on the number of personnel, the specifics of technological processes and air exchange requirements.

- Building configuration:The length and complexity of the pipeline system, the number of bends, the diameter of the air ducts.

These parameters help determine what volume of air (in m³/h) should move the fan and what pressure (in PA) must be created to ensure effective air exchange.

2.2 Technical parameters of the fanhttp://www.hengdingfan.ru

When choosing a model of the axial fan, the following technical parameters should be taken into account:

- Productivity (Q, m³/h):This indicator determines how much air the fan is able to move per unit of time. For large factories, a fan with high performance is required.

- Working pressure (PA):The longer and more complicated the air duct system, the higher the pressure created by the fan should be.

- The power of the electric motor (kW):The capacity of the fan depends on the power to overcome the resistance of the system and ensure stable operation.

- Rotation speed (rpm):Determines the dynamics of the air flow. Higher speeds allow you to create a more powerful stream, but can lead to an increased level of noise and energy consumption.

- Diameter of the air duct (mm):It is important to consider for calculating resistance in the system. The selection of suitable diameter helps to reduce pressure loss and optimize the fan.

- Protection and class of isolation:To work in difficult conditions (for example, with high humidity or an aggressive environment), choose equipment with IP55 protection and H. insulation class.

3. Calculation and selection of a suitable fan

3.1 Analysis of operating conditions

The first step is to conduct a thorough analysis of operating conditions at your factory. This includes:

- Measurement of the size of the premises and pipelines:Determine the length, diameter and configuration of the air duct.

- Determination of the required volume of air:Calculate how much air is needed to maintain an optimal microclimate. For example, in production workshops a certain number of air exchange per hour is recommended.

- Calculation of static pressure:Consider friction losses in pipes, the number of bends and the resistance of fittings. The greater the resistance, the higher the operating pressure of the fan should be.

3.2 Technical calculations

After collecting data, it is necessary to conduct calculations:

- Air flow volume (Q, m³/h):Determine the necessary volume of air based on the area and height of the premises.

- Static pressure (PA):Calculate the total pressure that must be overcome to ensure effective air exchange.

- Energy consumption and efficiency:Evaluate which electric motor (power and efficiency) will be able to ensure stable fan operation under these conditions.

3.3 Choosing a fan modelhttp://www.hengdingfan.ru

Based on the calculations, the axial fan model is selected, which satisfies the following requirements:

- Productivity corresponding to the calculated volume of air.

- Working pressure sufficient to overcome the resistance of the system.

- The optimal engine power that provides energy efficiency.

- Low noise and vibration level to create comfortable working conditions.

- High reliability, durability and compliance with protection standards (IP55, isolation class H).

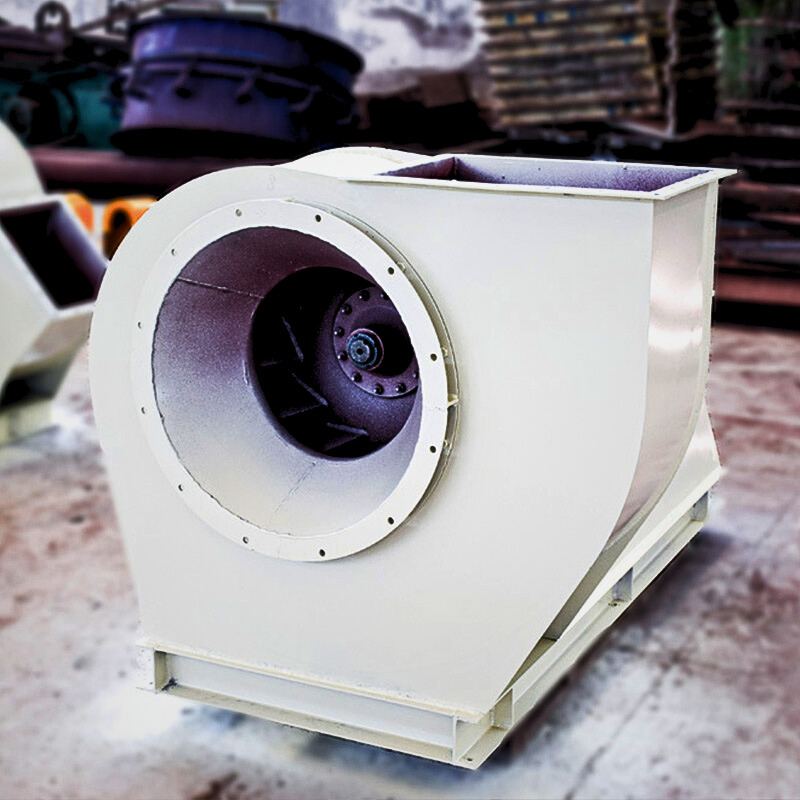

4. The use of radial centrifugal fans

Although the title is dedicated to the choice of axial fan, often for complex ventilation systems, especially with long pipelines, the optimal solution is radial centrifugal fans. They have the following advantages:

- High static pressure:They are able to overcome significant resistance in the air ducts system.

- Vibration resistance:Thanks to a balanced structure, they work with smaller vibrations, which reduces the noise level.

- Energy efficiency:Modern models are equipped with inverter control systems, which allows you to regulate speed and reduce energy consumption.

- Simplicity of integration:Easily integrated into existing ventilation systems, providing a stable and uniform air flow.

5. Practical examples and cases

5.1 Example from Russia

At one of the large industrial enterprises in Russia, the ventilation system was modernized. Using the exact calculations of the parameters of pipelines and the correct selection of equipment, including the choice of axial fan with optimal technical characteristics (productivity, pressure, engine power), it was possible to increase the volume of the displaced air by 20% and reduce energy consumption by 15%. The results of the project made it possible to significantly improve working conditions in production workshops and increase the overall security of the enterprise.

5.2 Example from Kazakhstan

In the mine in Kazakhstan, radial centrifugal fans were installed, designed to work in conditions of long and winding pipelines. Thanks to thorough calculations and choosing a model with sufficient power and high level of protection (IP55, isolation class H), the ventilation system provided a stable flow of fresh air, reducing the risk of explosive gases and increasing the reliability of the equipment. This contributed to an increase in the life of the ventilation system and a decrease in operating costs.

5.3 Example from Europe

In one of the large shopping centers in Europe, the ventilation system using modern fans was optimized. A thorough analysis of the conditions, the calculation of the necessary parameters and the integration of the monitoring system made it possible to choose equipment that provided uniform distribution of air in long ducts, minimized the noise level and reduced power consumption. The result was the creation of a comfortable microclimate for visitors and employees, as well as a significant decrease in operating costs.

6. Recommendations for optimizing the ventilation system

6.1 Analysis of operating conditions

Before choosing equipment, it is necessary to conduct a detailed analysis of the conditions:

- Determine the size and layout of the factory premises.

- Calculate the volume of air and static pressure in the system.

- Consider the features of pipelines: length, diameter, number of bends.

- Evaluate environmental conditions: temperature, humidity, pollution level.

6.2 Choosing reliable equipment

Pay attention to the technical characteristics of the fans, such as performance, pressure, power and noise level. The parameters of protection are no less important - the availability of IP55 certificates and the isolation class H provide reliable work in difficult conditions.

6.3 Integration with modern management systems

The introduction of monitoring and automation systems allows in real time to control the fan operations, quickly respond to deviations and conduct preventive maintenance. This provides optimal operation of the system and reduces energy consumption.

6.4 Regular maintenance

Organization of planned maintenance is a key factor in ensuring the long -term operation of equipment. Regular checks, cleaning filters, lubrication of bearings and replacing worn parts help to reduce the risk of accidents and extend the fan service.

7. Economic efficiency and long -term benefits

7.1 Reducing operating costs

The optimally selected fan, taking into account all the calculated parameters, can significantly reduce energy costs and operating costs. Energy efficient equipment requires minimal maintenance costs, which positively affects the general financial indicators of the enterprise.

7.2 increased performance

An effective ventilation system helps to improve working conditions at the plant, reduce thermal loads on equipment and increase overall performance. This is especially important for large industrial facilities, where stable air exchange is the key to safety and production efficiency.

7.3 Return of investment

Investments in high -quality ventilation equipment are paid off by reducing electricity costs, reducing the number of emergency stops and increasing the service life of equipment. Optimization of the operation of the ventilation system leads to significant savings in a long -term basis.

8. Conclusionhttp://www.hengdingfan.ru

The choice of a suitable model of the axial fan depending on the scale of your plant is a key factor for ensuring effective, reliable and economical operation of the ventilation system. A thorough analysis of operating conditions, accurate calculations of the necessary parameters and the selection of high -quality equipment with IP55 protection and the insulation class H can significantly increase performance and reduce operating costs.

Practical examples from Russia, Kazakhstan and Europe demonstrate that competent design and installation of the ventilation system ensure the long -term stability of the enterprise. The integration of modern monitoring and automation technologies, as well as regular maintenance - these are the main conditions that contribute to increasing energy efficiency and production safety.

When choosing an axial fan, take into account not only its main technical parameters, but also the features of your plant to ensure the optimal ratio between performance, energy consumption and operational costs. Modern solutions allow you to create a ventilation system that will work effectively and reliably, helping to increase the overall economic efficiency of your enterprise.