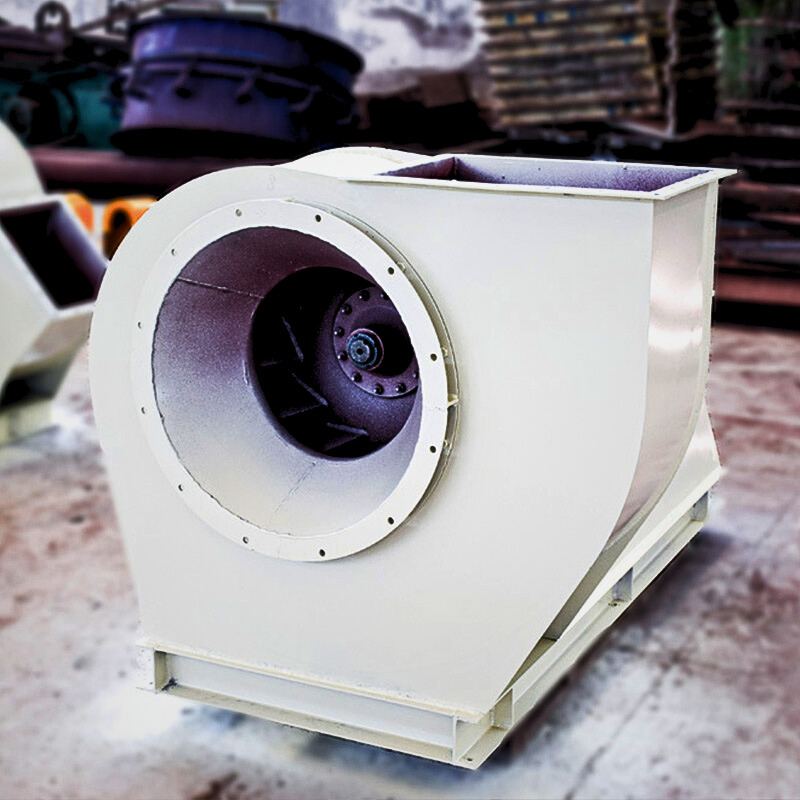

The main ventilation fans: a reliable and energy -efficient solution for optimal air exchange, safety and comfort at industrial facilities

2025-03-12

Effective ventilation is the key to safety, comfort and high performance at any industrial enterprise. In the conditions of constantly growing requirements for energy efficiency and reliability of equipment, ventilation systems play a key role in ensuring optimal air exchange. In particular, the main ventilation fans are the central element of such systems. They not only provide an influx of fresh air, but also contribute to the removal of harmful gases and pollution, supporting a stable microclimate in the rooms. In this article, we will consider in detail how the main ventilation fans provide effective ventilation, what technical characteristics should be taken into account when choosing them, as well as give successful cases of introducing such systems.

1. The role of the main ventilation fans in industry

1.1 Ensuring safety and air quality http://www.hengdingfan.ru

At industrial facilities, such as factories, mines, shopping centers and office buildings, maintaining the optimal level of oxygen and removing harmful gases play a decisive role. The main ventilation fans provide:

- Removing harmful substances:Effective removal of dust, chemical vapors, carbon monoxide and methane gas prevents emergency situations.

- Providing fresh air:Constant air updating helps to maintain a normal level of oxygen and improves the microclimate in the rooms.

- Reducing the risk of explosive conditions:Proper ventilation helps to avoid the accumulation of explosive gas mixtures, which is critical for mines and chemical industries.

1.2 Energy efficiency and savings

In the context of increasing energy prices, enterprises strive to optimize electricity consumption. Fans of the main ventilation, having high energy efficiency, contribute to a decrease in operational costs. This is achieved at the expense of:

- Optimized structure:Modern models are designed in such a way as to provide maximum air exchange with minimal energy costs.

- Inverter control:Regulation of the fan rotation speed depending on current loads allows you to adapt the system and reduce energy consumption.

- Low noise level:Effective reduction of vibrations and noise reduces the load on the structure and ensures the durability of the equipment.

1.3 Comfort and performance

For commercial and office buildings, air comfort is of great importance. The main ventilation fans create favorable conditions for work and rest, contributing to:

- Improving microclimate:The uniform distribution of fresh air provides a comfortable temperature and humidity.

- Reducing the noise level:Modern systems work quietly, which improves working conditions and increases user satisfaction.

- Increased performance:Optimal air conditions contribute to improving the concentration and performance of personnel.

2. Technical characteristics of the main ventilation fans

When choosing a fan to ensure the main ventilation, it is important to consider the following technical parameters:

2.1 performance (Q)

The performance of the fan is measured in cubic meters of air moved per minute (m³/min). This parameter depends on the size of the object, the number of employees and the required air exchange frequency. For example, for large industrial facilities, a fan is required that can ensure the movement of tens of thousands of air per hour.

2.2 working pressure

The working pressure measured in Pascal (PA) determines the ability of the fan to overcome the resistance of the air duct system. The longer and more complicated the system, the higher the working pressure should be. The correct calculation of pressure avoids losses and ensure stable operation of the ventilation system.

2.3 power of the electric motor

The engine power (in kW) is directly related to the performance of the fan. A highly effective engine provides stable operation and reduces energy consumption, which is especially important for systems working around the clock. When choosing, it is important to take into account not only the rated power, but also the possibility of regulating the speed to optimize the work.

2.4 rotation speed

The rotation speed of fan blades, measured in speeds per minute (R/min), affects the creation of air flow and dynamic pressure. Higher rotation speed provides a more powerful flow, but can increase the noise and energy consumption.

2.5 diameter of the duct

The diameter of the air duct determines the volume of air, which can move through the system. The correspondence of the diameter of the fan compartment and pipelines allows you to minimize pressure losses and ensure the optimal distribution of air throughout the object.

2.6 additional characteristics

Important parameters are also noise, energy efficiency, durability, as well as compliance with protection requirements (for example, IP55) and isolation class (for example, class H). These parameters provide reliable operation of the equipment even in difficult operating conditions.

3. The use of main ventilation fans in various objects http://www.hengdingfan.ru

3.1 industrial enterprises

At large factories and production facilities, the main ventilation fans provide a stable air exchange necessary for cooling the equipment and creating a safe working microclimate. An effective ventilation system helps to remove hot air, reduce the risk of overheating of machine tools and increase overall performance.

3.2 mines and mines

In the mining industry, ventilation is of paramount importance for safety. The main ventilation fans in the mines are designed to remove explosive gases, such as methane, and maintain the optimal level of oxygen. This helps to prevent emergency situations and provides safe working conditions for miners.

3.3 transport systems

In metro systems, railway tunnels and automobile crossings, reliable ventilation is necessary to ensure the safety and comfort of passengers. The main ventilation fans in such objects play an important role in the removal of smoke and harmful gases, as well as in the regulation of temperature and humidity.

3.4 commercial and office buildings

In shopping centers, office complexes and other commercial buildings, it is important to create comfortable conditions for work and rest. The main ventilation fans contribute to the uniform distribution of fresh air, maintaining the optimal microclimate and a decrease in noise level, which positively affects the general comfort and productivity.

4. Examples of successful projects http://www.hengdingfan.ru

4.1 Example from Russia

At one of the large industrial enterprises in Russia, a ventilation system was modernized using the main ventilation fans. The calculation of the parameters of the pipeline system and the selection of optimal technical characteristics made it possible to increase the volume of the displaced air by 25% and reduce energy consumption by 18%. This improved the working conditions of personnel and increased production safety.

4.2 Example from Kazakhstan

In the mines of Kazakhstan, the installation of modern main ventilation fans significantly reduced the risk of explosive gases. The use of high -strength models with adjustable parameters provided a stable influx of fresh air, which contributed to an increase in safety at the mine and reducing the cost of maintaining the ventilation system.

4.3 Example from Europe

In one of the large shopping centers in Europe, a ventilation system was implemented, based on the use of main ventilation fans. Thorough optimization of the parameters of the system, including the calculation of the volume of air and static pressure, made it possible to create a comfortable microclimate, reduce noise and reduce energy consumption, which led to a significant reduction in operational costs and increase the overall efficiency of the building.

5. Practical recommendations for choosing and installing

5.1 Pre -analysis

Before choosing ventilation equipment, it is necessary to conduct a detailed analysis of operating conditions:

- Determine the size and layout of the object.

- Calculate the required volume of air flow and static pressure in the system.

- Consider the features of pipelines, their length, diameter and number of bends.

5.2 Selection of optimal technical characteristics

Based on the calculations, select fans with the desired performance, working pressure, power and noise level. Pay special attention to such parameters as the IP55 protection and the isolation class H, which provide reliable work in difficult conditions.

5.3 Professional installation and integration

The correct installation of ventilation equipment plays a decisive role:

- Provide the accurate alignment of the fan with the air duct system.

- Use high -quality fasteners and sealing materials.

- Test the system after installation to verify compliance with the calculated parameters.

5.4 regular maintenance

Planned service - the key to the durable and efficient operation of the ventilation system:

- Carry out regular cleaning of filters and ducts.

- Monitor the condition of the equipment using monitoring systems.

- Teach personnel to operating and maintenance rules.

6. Economic efficiency

6.1 Reducing operating costs

Optimization of the ventilation system due to the choice of high -quality equipment can significantly reduce electricity costs and maintenance. Energy efficient fans with optimal parameters contribute to a decrease in operational costs, which positively affects the overall profitability of the enterprise.

6.2 Improving safety and performance

Effective ventilation improves working conditions, reduces the risk of accidents associated with the accumulation of harmful gases, and increases the overall performance of the enterprise. This, in turn, affects the quality of the products and the satisfaction of employees.

6.3 Return of investment

Investments in high -quality ventilation equipment are paid off by reducing electricity costs, reducing the downtime of equipment and increasing the reliability of the system. The long -term operation of the optimized ventilation system helps to improve the financial indicators of the enterprise and increase the profit.

7. Conclusion http://www.hengdingfan.ru

The choice of a suitable fan for the ventilation system, taking into account the length of the pipelines and the specifics of the facility, is the key to the successful operation of the enterprise. The correct analysis of the conditions, the exact calculation of the necessary parameters, the choice of high -quality equipment and professional installation - all this allows you to create an effective and economical ventilation system.

Examples of successful projects from Russia, Kazakhstan and Europe confirm that competent design and optimization of the work of ventilation systems lead to a significant reduction in energy consumption, increasing safety and improving labor conditions. The use of modern monitoring and automation technologies, regular maintenance and staff training are integral elements of strategies for ensuring long -term stability and economic efficiency of the system.

Thus, investments in high -quality ventilation equipment are not only a technical solution, but also a strategic step towards improving the performance, safety and economic benefits of your enterprise.