The main ventilation fans to ensure reliable ventilation of large objects: how to choose, install and operate with maximum efficiency

2025-03-13

Effective ventilation is the basis for safety, comfort and energy efficiency in large industrial, commercial and public facilities. In the conditions of modern construction and operation of buildings and structures, the main ventilation system plays a key role. The main ventilation fans provide an influx of fresh air, remove contaminated air, maintain optimal climatic conditions and, most importantly, contribute to a decrease in energy consumption.

The setting of the correct ventilation system begins with the choice of high -quality equipment. ExactlyFans of the main ventilationThey make up the “heart” of the system on which the reliability of the entire ventilation network depends. In this article, we will consider what technical parameters and requirements must be taken into account when choosing fans, how to properly carry out installation and maintenance, as well as give examples of successful projects to install such systems.

1. The value of the main ventilation fans

1.1 Role of ventilation in large facilities

In large industrial enterprises, shopping centers, office buildings and transport facilities, not only the stable supply of fresh air is important, but also the effective removal of pollution, heat and excess moisture. Ventilation systems perform the following functions:

- Providing the influx of fresh air:This is necessary to maintain a normal level of oxygen, which is especially important in conditions of high density of people and production processes.

- Removing harmful substances:Ventilation systems allow you to remove dust, gases and other pollutants, creating a safe working environment.

- Temperature and humidity regulation:Fans help to maintain optimal climatic conditions, preventing equipment overheating and improving room comfort.

1.2 Why are the main ventilation fans important

The main ventilation fans provide centralized air flow control in a large facility. They are a key link that:

- Provides uniform distribution of air throughout the system.

- Supports stable pressure in long pipelines.

- Allows optimizing energy consumption thanks to the use of modern management technologies.

- It guarantees a high level of safety due to the effective removal of explosive gases and maintaining the optimal microclimate.

2. Technical parameters of the main ventilation fans

When choosing fans for the main ventilation system, attention should be paid to a number of technical characteristics that directly affect the effectiveness of the system.

2.1 performance (Q, m³/min)

The performance of the fan determines the volume of air, which the device can move in a certain period of time. This parameter depends on the size of the room, the requirements for the air exchange and the specifics of the object. For example, large industrial enterprises require high -performance fans to ensure adequate air exchange.

2.2 working pressure (PA)

Working pressure is the ability of the fan to overcome the resistance of the pipeline system. In systems with long and winding ducts, a fan is required that can create sufficient pressure for stable operation of the entire system. The calculation of static pressure includes an analysis of the length of the pipes, the number of bends, the diameter of the ducts and other factors.

2.3 electric motor power (kW)

The power of the electric motor directly affects the performance and energy consumption of the fan. When choosing equipment, it is important to choose an engine that will provide the necessary power to move the required volume of air at minimum electricity costs.

2.4 rotation speed (R/min)

The speed of rotation of the blades affects the kinetic energy created by the fan. The high speed of rotation can provide a more powerful air flow, but it can also increase the noise and energy consumption. The optimal balance between speed and energy efficiency is critical for the successful operation of the system.

2.5 IP55 protection and isolation class H

To ensure reliable operation of the fan in difficult operating conditions, the presence of IP55 protection is extremely important, which guarantees the stability of the device to dust and jets of water, as well as the isolation class H, which ensures the operation of the electric motor at high temperatures up to 220 ° C. These parameters are especially relevant for objects with an aggressive environment and long pipeline systems.

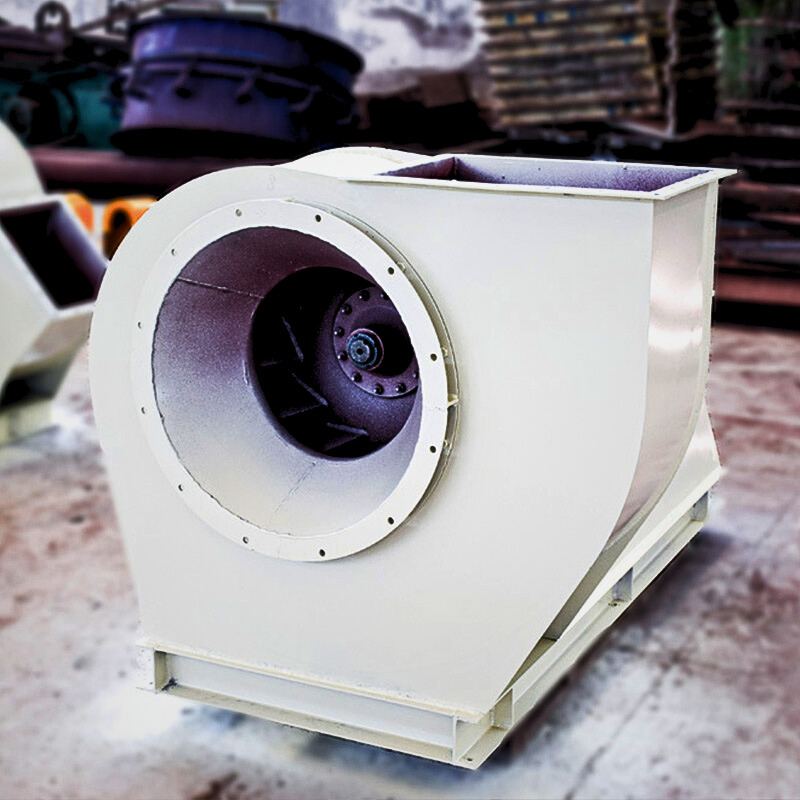

3. The use of radial centrifugal fans in the main ventilation systems

3.1 Industrial cooling and ventilation

At large factories and production complexes, radial centrifugal fans are used to effectively cool the equipment and ensure stable ventilation. They help to remove excess heat, prevent overheating of machine tools and create optimal conditions for staff. The high performance of such fans allows for stable air exchange even in high loads.

3.2 ventilation of mines and underground structures

In the mining industry, ventilation is a security key. Radial centrifugal fans, calculated taking into account long pipelines and high static pressure, provide a stable supply of fresh air, preventing the accumulation of explosive gases and improving the working conditions of the miners. Reliable ventilation systems with IP55 protection and isolation class H help increase safety in mines and mines.

3.3 ventilation of trade and office buildings

In large commercial and office buildings, effective ventilation helps to maintain a comfortable microclimate, improve working conditions and reduce energy consumption. Radial centrifugal fans, properly selected in terms of technical characteristics, provide uniform distribution of fresh air and the minimum noise level, which is especially important for creating a favorable working environment.

4. Examples of successful projects http://www.hengdingfan.ru

4.1 Example from Russia

At one of the large industrial enterprises in Russia, a ventilation system was modernized with the installation of radial centrifugal fans designed to work in long pipelines. Due to the exact calculations of the parameters and the optimal selection of equipment, including the IP55 protection and the isolation class H, the total air flow increased by 25%, and the energy consumption decreased by 18%. This made it possible to significantly increase the safety and productivity of the plant.

4.2 Example from Kazakhstan

In the mines of Kazakhstan, the installed radial centrifugal fans provided stable ventilation even in conditions of complex and long ducts. The optimization of the parameters of the system and the introduction of intellectual monitoring systems have reduced the risk of explosive gases accumulation and increase the life of the equipment. Regular maintenance and the use of high -quality equipment contributed to increasing safety and reducing operating costs.

4.3 Example from Europe

In one of the large shopping centers in Europe, the ventilation system using radial centrifugal fans was optimized. Due to the exact calculation of static pressure, the optimal selection of parameters and the correct installation, it was possible to create an uniform distribution of air, reduce the noise level and reduce energy consumption. The result was significant savings in the operation and increase of comfort for visitors and employees of the building.

5. Practical recommendations for choosing and installing

5.1 Pre -analysis

Before choosing a fan, it is important to conduct a detailed analysis of operating conditions:

- Measure the length, diameter and configuration of pipelines.

- Determine the required volume of air (m³/min) and static pressure (PA).

- Consider the environmental conditions: temperature, humidity, the presence of dust and aggressive substances.

5.2 exact calculation of parameters

Calculate the necessary parameters of the ventilation system using the methods of computing hydrodynamics (CFD) to optimize the angle of air output and select the optimal characteristics of the fans. Accurate calculations will help to determine what power, rotation speed and performance is enough to meet the needs of your object.

5.3 Choosing a reliable manufacturer

Cooperation with trusted suppliers of ventilation equipment guarantees high quality products, the availability of certificates and professional technical support. Pay attention to the experience of the company and customer reviews to be sure of the reliability of the acquired equipment.

5.4 Integration with monitoring systems

Modern monitoring systems allow you to track the fan operation in real time. Installation of temperature sensors, pressure, vibration and noise helps to timely identify deviations and conduct preventive maintenance, which increases the overall efficiency of the system.

5.5 Professional installation and maintenance

Proper installation of equipment is the key to its long -term and stable operation. Provide the professional installation of fans using high -quality fasteners and sealing materials. Regular maintenance, including cleaning, lubrication of bearings and replacing worn parts, significantly extends the service life of the system and reduces operating costs.

6. Economic efficiency

6.1 Reduced energy cost

An optimally selected and correctly installed fan can significantly reduce power consumption, which leads to a reduction in operating costs. Energy efficient models with modern electric motors and inverter management allow us to adapt the operation of the system depending on current loads.

6.2 increased performance

Effective ventilation helps to improve working conditions and cooling equipment, which positively affects the performance of the enterprise. Stable air exchange helps to avoid overheating of machines, reduces the risk of emergency situations and increases the total volume of moved air.

6.3 Long -term benefits

Investments in high -quality ventilation equipment are paid off by increasing the service life of the system, reducing the costs of repair and maintenance, as well as an increase in the overall economic efficiency of the enterprise. A reliable and optimized ventilation system helps to improve financial indicators by reducing electricity costs and eliminating emergency downtime.

7. Conclusion http://www.hengdingfan.ru

The choice of a suitable radial centrifugal fan, taking into account the parameters of the pipeline system, is a key factor for ensuring effective, reliable and economical operation of the ventilation system. A thorough analysis of operating conditions, accurate calculation of the necessary parameters, the choice of high -quality equipment with IP55 protection, the insulation class H and reliable fasteners, as well as the integration of modern monitoring systems, can significantly reduce energy consumption, increase the safety and durability of the system.

Practical experience confirmed by successful projects in Russia, Kazakhstan and Europe demonstrates that competent design and professional installation of ventilation systems pay off by increasing productivity and reducing operating costs. Investments in high -quality equipment and regular maintenance is a strategically important step to ensure the long -term stable work of your enterprise.