The role of the front lattice in pipe fans

2025-03-11

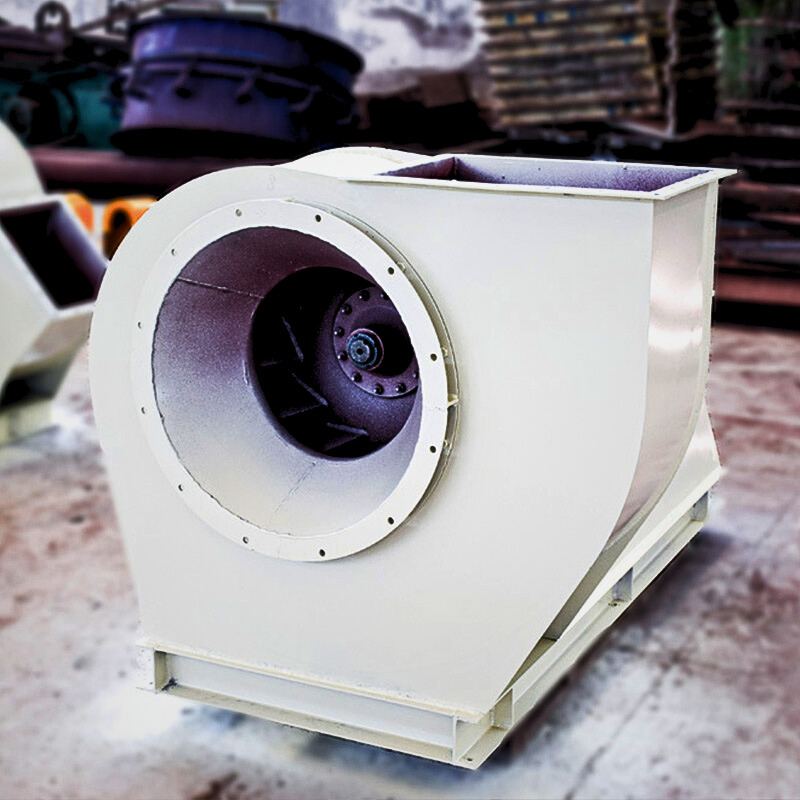

The effective operation of ventilation systems is crucial for ensuring safety and comfort at industrial, commercial and residential facilities. Pipe fans are widely used to create a stable air flow in ventilation systems, providing the necessary air exchange in rooms with long ducts. However, in addition to the main elements, such as the impeller, the electric motor and the case, the front grate of the fan plays an important role in the system. Despite the apparent insignificance, this component performs several critical functions that affect the safety, efficiency and durability of all equipment. http://www.hengdingfan.ru

In this article, we will examine in detail the role of the front lattice in pipe fans, its functional tasks, the impact on the operational characteristics of the system, as well as give practical recommendations for the choice, installation and maintenance of this element.

1. Functional purpose of the front lattice

1.1 Protection of internal components

The front lattice performs an important protective function, preventing the hit of large particles, dust, garbage and other pollutants into the working parts of the fan. This is especially true for objects with intensive movement of people, transport or in industrial conditions, where various mechanical impurities are present in the air. Protecting the impeller and electric motor, the grate helps to reduce the risk of damage to the equipment and extends the service life.

1.2 Safety

The lattice also plays a key role in ensuring security. It prevents random contact with the moving parts of the fan, which reduces the risk of staff injuries during maintenance or random touch. In addition, the grill helps to prevent foreign objects from entering the system, which can cause an imbalance and emergency situations.

1.3 Air flow optimization

The front lattice is able to influence the distribution of the air flow entering the fan. A well -designed grille helps to evenly distribute air throughout the working element, providing optimal aerodynamic conditions. This helps to increase the efficiency of the fan, reduce pressure losses and improve the energy efficiency of the system.

2. Technical characteristics and design features

2.1 Materials of manufacture

The front grill is made of various materials, each of which has its own advantages:

- Metal lattices:Often made of stainless steel or aluminum. They have high strength, durability and resistance to corrosion. Stainless steel is especially recommended for aggressive environments.

- Plastic grilles:They have lightness and high resistance to chemicals. They are often used in systems where weight savings and cost reduction are important.

- Composite materials:The use of modern composites allows you to achieve an optimal combination of strength and lightness, which is especially important for objects with high energy efficiency requirements.

2.2 lattice design

The design of the front lattice can vary depending on the fan model and operating conditions:

- Mesh design:Provides a high degree of filtration and protection, preventing large particles. Such a lattice is suitable for systems with a high degree of air pollution.

- Lamelian structure:Allows you to more evenly distribute the air flow, which improves the aerodynamics of the system. Suitable for objects where air flow optimization and reduction of energy consumption are important.

- Combined structures:The advantages of the mesh and lamella design are combined, providing both protection and optimal air distribution.

2.3 Dimensions and geometry

The dimensions of the front lattice must correspond to the parameters of the fan. The geometry of the lattice affects:

- The volume of incoming air:The size of the grate cells determines how much air can pass through it without significant losses.

- Degree of protection:A small grid provides a higher level of protection, but can reduce the flow of air. The optimal ratio of the size of the cells and the total area of the lattice allows you to achieve the balance between protection and performance.

3. The effect of the front lattice on the operational characteristics of the fan

3.1 Energy efficiency

The correctly selected front grill helps to reduce pressure losses in the system. This directly affects the power consumption of the fan, since with an optimal air flow, the electric motor operates in a more effective mode. The use of high -quality materials and the optimal lattice design allows you to reduce energy costs and increase the efficiency of the entire system.

3.2 noise level

The aerodynamic characteristics of the lattice affect the distribution of air flow and, as a result, on the noise level created by the fan. The grate that provides uniform air distribution helps to reduce turbulence and vibration, which reduces noise. This is especially important for objects where compliance with noise levels is required, such as office buildings and shopping centers.

3.3 Durability and reliability

The front lattice protects the key elements of the fan from pollution and mechanical damage. This allows you to extend the service life of the impeller, electric motor and other components of the system. Regular cleaning and preventive maintenance of the lattice contributes to the stable operation of the equipment, reducing the risk of breakdowns and accidents.

4. The use of radial centrifugal fans with the front lattice

4.1 Industrial use

At industrial enterprises, where the operating conditions are often harsh, the front grille plays a decisive role in protecting equipment from dust, pollution and aggressive chemicals. Radial centrifugal fans equipped with high -quality grilles provide reliable ventilation of production facilities, maintaining optimal temperature and stable air exchange. This is especially important for cooling and ventilation systems in workshops, where equipment overheating can lead to serious breakdowns.

4.2 ventilation of mines and mines

In the mining industry, stable ventilation is a security key. The front lattice in such systems prevents large particles, dust and other pollutants into the fan, which can cause malfunctions and accidents. Reliable protection of ventilation equipment helps to maintain the optimal level of oxygen and prevent the accumulation of explosive gases, ensuring the safety of miners.

4.3 Application in transport systems

In tunnels, metro and other underground communications, the front grill helps to ensure high -quality ventilation and removal of harmful gases. Radial centrifugal fans with the optimal grill provide uniform air distribution, which improves working conditions and increases the safety of passengers in case of emergency situations.

5. Practical recommendations for the selection and maintenance of the front lattice

5.1 selection of material and design

When choosing the front lattice, the operating conditions should be taken into account:

- For aggressive media, metal or composite grilles of stainless steel or titanium alloys are preferred.

- For systems with a high degree of air pollution, you can use mesh structures with small cells that provide a high level of filtration.

- In rooms where a high volume of air is required with minimal pressure losses, the optimal solution will be a lamella or combined structure.

5.2 Technical calculations and modeling

The use of modern methods, such as CFD modeling, allows you to accurately determine the optimal geometry and sizes of the lattice for a specific ventilation system. This helps minimize pressure losses and ensure uniform distribution of air flow.

5.3 installation and installation

The correct installation of the front lattice is crucial:

- Provide the accurate mounting of the grate to the fan housing using high -quality fasteners.

- Check the tightness of the compounds to prevent air leaks.

- If necessary, install additional protective elements to increase the stability of the structure.

5.4 regular maintenance

To maintain optimal operation of the ventilation system, it is necessary to regularly maintain the front lattice:

- Regularly clean the grate from dust and pollution.

- Carry out examinations for mechanical damage or wear.

- If necessary, replace worn elements to maintain the reliability and effectiveness of the system.

6. Examples of successful projects http://www.hengdingfan.ru

6.1 Industrial enterprise in Russia

At one of the large factories in Russia, a ventilation system was introduced, equipped with radial centrifugal fans with high -quality front lattices. Due to the optimization of the lattice design, it was possible to reduce pressure losses by 10% and increase the total air flow by 20%. This led to a significant decrease in energy consumption and an increase in the efficiency of cooling of production equipment.

6.2 Mine in Kazakhstan

In one of the mines of Kazakhstan, the use of the front lattice in ventilation systems turned out to be a key element that provides stable fan operation in conditions of high dust and aggressive environment. The lattice prevented large particles entering the fan, reduced the risk of damage to the equipment and increased the overall reliability of the ventilation system, which contributed to an increase in safety at the mine.

6.3 Transport system in Europe

In one of the large metro tunnels in Europe, a ventilation system was modernized using radial centrifugal fans equipped with front lattices with optimal configuration. The result was a significant optimization of the air flow, a decrease in the noise level and a decrease in energy consumption, which provided comfortable conditions for passengers and increased the reliability of the system as a whole.

7. Economic efficiency and long -term benefits

7.1 Reducing operating costs

The optimized front grate helps to reduce pressure losses, which directly reduces power consumption. The energy -efficient operation of the ventilation system reduces the operational costs of the enterprise, and reliable protection of the equipment reduces the cost of repair and replacement of parts.

7.2 increased performance

Effective ventilation, provided with a high -quality front grill, improves the working conditions of equipment and personnel, which helps to increase the overall performance of the enterprise. The optimal distribution of air flow prevents overheating of the equipment and reduces the risk of emergency situations.

7.3 The durability of equipment

Regular maintenance and the use of high -quality protective elements, such as the front grill, increase the life of the fans and other components of the ventilation system. This helps to reduce the total cost of operation and increases the economic efficiency of the enterprise.

8. Practical recommendations for the implementation of the system

8.1 Conducting a detailed analysis of operating conditions

Before choosing equipment, conduct a thorough analysis of the characteristics of the object:

- Determine the level of air pollution and the presence of large particles.

- Calculate the required volume of air and static pressure.

- Consider the features of the environment: temperature, humidity and aggressiveness of the environment.

8.2 Cooperation with trusted suppliers

Choose equipment from reliable manufacturers that provide quality certificates and warranty service. Experienced suppliers will help you choose the optimal solutions for your facility, taking into account all the technical requirements.

8.3 Implementation of monitoring systems

Integrate modern monitoring systems that will monitor the condition of the ventilation system in real time. The use of pressure sensors, temperature and noise levels will help to quickly respond to any deviations from normal work and conduct preventive maintenance.

8.4 staff training

Qualified personnel are the key to the successful operation of the ventilation system. Organize regular training of employees on maintenance, installation and proper operation of the front lattice and all ventilation equipment.

9. Conclusion

The front grill of a pipe fan is, it would seem, a small detail, but it plays a critical role in ensuring stable, energy -efficient and reliable operation of the ventilation system. An optimally selected and correctly installed grate protects the internal components of the fan from pollution, reduces pressure losses and improves the distribution of air flow. This leads to a decrease in energy consumption, an increase in the life of the equipment and increase the overall system performance.

Practical experience confirmed by successful cases in industrial enterprises, mines and transport systems shows that investments in high -quality ventilation equipment with correctly selected protective elements are paid off by reducing operational costs and increasing safety. To achieve the best results, it is recommended to conduct a detailed analysis of operating conditions, cooperate with trusted suppliers, introduce modern monitoring systems and train staff. Such an integrated approach will allow your enterprise to ensure long -term and stable operation of the ventilation system, creating optimal conditions for work and increasing economic efficiency. http://www.hengdingfan.ru