Are the main fans of your plant correctly installed? Important points of installation for maximum efficiency

2025-03-13

An effective ventilation system- This is the basis of safe and productive production. The main fans play a key role in ensuring air circulation, removing harmful gases, dust and heat, which is critical to maintain the optimal microclimate at the factory. However, even the most high -quality equipment can work inefficiently if the installation is done incorrectly. Installation errors can lead to increased energy costs, a decrease in productivity and even a threat to staff safety.

In this article, we will consider in detail why the correct installation of the main fans is so important for your plant, which aspects should be taken into account when installing, and how to ensure reliable and energy -efficient operation of the ventilation system. We will discuss the technical nuances, we will give practical recommendations and real examples of successful installation, which will help you make sure that you have the correct installation of your equipment.

1. The value of the correct installation of the main fans

1.1 Ensuring effective air exchange

The main fan is the heart of the ventilation system responsible for creating a powerful air flow. Its main function is to ensure the influx of fresh air and the removal of contaminated air from production premises. If the installation of the fan is made with errors, this can lead to a decrease in air volume, which will negatively affect the quality of the microclimate, safety and efficiency of the entire plant.

1.2 Reducing electricity costs

A properly installed fan operates in optimal modes, which can significantly reduce energy consumption. Incorrect connection or inconsistency of the system with requirements can lead to excess loading on the engine, increased energy consumption and, as a result, an increase in operating costs.

1.3 Safety increase

In factories where explosive mixtures are possible, reliable operation of the ventilation system is a matter of paramount importance. Incorrect installation of fans can lead to ineffective removal of harmful gases, which increases the risk of emergency situations and threaten employees.

1.4 Increase in equipment service life

High -quality installation and regular maintenance of the main fans help to reduce wear of mechanical components, such as bearings and fasteners. This increases the service life of the equipment and reduces the cost of repair and replacement of parts.

2. Key aspects of the installation of the main fans

2.1 accurate alignment and balancing

One of the main errors in the installation of ventilation equipment is incorrect leveling. The fan must be accurately installed relative to the air duct system. Small deviations can lead to imbalance, which causes increased vibrations, noise and accelerated wear of bearings.

- Recommendation:Use laser levels and balancing devices to check the leveling. Regularly carry out the balancing of the system to ensure stable rotation.

2.2 reliable mount and fixation

Fasteners, such as screws and bolts, play a decisive role in the reliability of installation. Incorrect mount can lead to a fan displacement, an increase in vibrations, and even breakdowns.

- An important nuance:Two types of screws can be used in the design - ordinary and high -strength. For high mechanical load and vibration conditions, it is recommended to use high -strength screws that will provide reliable fastening even in extreme conditions.

2.3 Electric connection and grounding

The correct electrical connection and reliable grounding are mandatory for the safety of fan operation. Errors in the connection can lead to overheating of the electric motor, short circuits and other emergency situations.

- Recommendation:Follow all electrical safety standards and carry out regular grounding checks. Use high -quality cables and connecting elements to ensure stable operation of the system.

2.4 tightness of the air duct system

The effectiveness of the ventilation system largely depends on the tightness of the joints of the air ducts. Air leaks can reduce the total volume of moved air and increase energy consumption.

- Recommendation:Use high -quality sealing materials and control the tightness after installation. Regularly check the condition of the connections and, if necessary, carry out repairs.

2.5 Integration with control and monitoring systems

Modern ventilation systems are equipped with intellectual monitoring systems that allow real time to track the work of equipment. This helps to quickly identify deviations and conduct preventive measures.

- Recommendation:Integrate fans with automatic control systems, which allow you to adjust operation parameters (for example, rotation speed) depending on current conditions. This significantly increases energy efficiency and reduces the risk of accidents.

3. Technical parameters affecting the choice of fan

When choosing the main fan for the plant, the following technical parameters must be taken into account:

- Air volume (m³/h):This indicator determines how much air the fan is able to move per unit of time. It is calculated on the basis of the size of production facilities and air exchange requirements.

- Working pressure (PA):It is important to overcome the resistance of the air duct system. The longer the pipeline and more bends, the higher the pressure created by the fan should be.

- The power of the electric motor (kW):It affects the overall performance and energy efficiency of the system. A balance between sufficient power and minimal energy consumption is required.

- Rotation speed (rpm):The optimal speed of rotation of the blades affects the creation of a stable air flow and minimization of energy.

- IP55 protection:It guarantees that the equipment is resistant to dust and jets of water from all directions, which is especially important for working in aggressive conditions.

- Isolating class h:It provides reliable operation of the electric motor at high temperatures up to 220 ° C, which is important for industrial objects with high thermal loads.

These parameters allow you to determine which fan will be the most effective for the specific conditions of your plant.

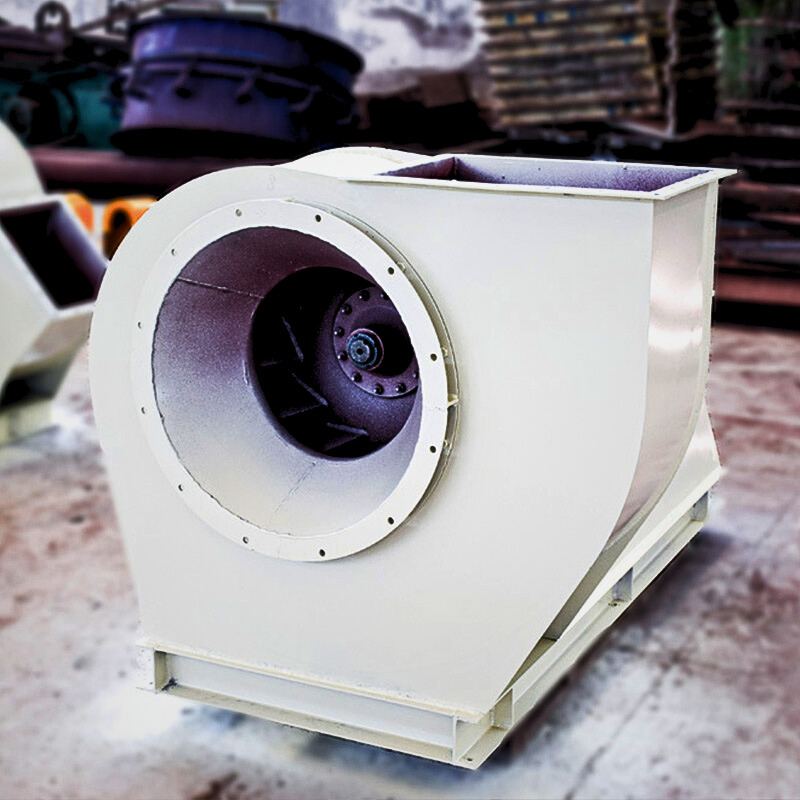

4. The use of radial centrifugal fans in factories

4.1 Industrial cooling

In large factories, radial centrifugal fans are used to cool equipment and production lines. An effective ventilation system helps to remove excess heat, preventing equipment overheating and reducing the risk of its breakdowns.

- Advantages:High performance, stable air flow, reduction of energy consumption and an increase in the life of the equipment.

4.2 Ventilation of industrial premises

Effective ventilation is a key element of creating an optimal microclimate in production. Radial centrifugal fans allow maintaining constant air exchange, removing dust, chemical pairs and other pollutants from production workshops.

- Advantages:Improving working conditions, increasing productivity and safety, reducing the risk of fire hazardous situations.

4.3 Providing ventilation in complex systems

At objects with long pipelines and numerous bends, the installation of the correct fan allows for stable pressure and uniform distribution of air throughout the system. This is especially important for mines, tunnels and other underground facilities where effective ventilation is critical for safety.

- Advantages:Optimization of air flow, reduction of energy consumption, increasing reliability and safety.

5. Examples of successful projects

5.1 Example from Russia

At one of the large factories in Russia, the ventilation system using radial centrifugal fans was modernized. Having carefully analyzed the operating conditions, the experts conducted the necessary parameters (air volume, pressure, engine power) and chose fans with IP55 protection and the insulation class H. The result was an increase in the volume of the displaced air by 20% and a decrease in energy cost by 15%, which significantly increased the efficiency of the work and improved the working conditions of employees.

5.2 Example from Kazakhstan

In the mines of Kazakhstan, to ensure stable ventilation in the conditions of long and winding pipelines, a ventilation system was introduced using modern radial centrifugal fans. Thanks to the exact calculations and professional installation, the fans were able to provide the necessary working pressure, which prevented the accumulation of explosive gases and increased the safety of mine work. The use of equipment with IP55 protection and the isolation class H has ensured the durability of the system even in an aggressive environment, which made it possible to reduce the cost of maintenance.

5.3 Example from Europe

In one of the large shopping centers in Europe, a ventilation system was modernized, focused on creating a comfortable microclimate for visitors and employees. Optimized radial centrifugal fans installed in long ducts provided uniform distribution of air at a minimum noise level. Thanks to the automatic control system and constant monitoring, energy costs were reduced, and operating costs were minimized. The selection of equipment with IP55 protection and the insulation class H has become the key to stable operation of the system in conditions of high humidity and temperature.

6. Practical recommendations

6.1 detailed analysis

Before choosing a fan, conduct a thorough analysis of the operating conditions of your plant:

- Measure the length and configuration of pipelines.

- Calculate the required volume of air (m³/h) and static pressure (PA).

- Determine the parameters of the environment (temperature, humidity, level of pollution).

6.2 Choosing high -quality equipment

Cooperate with trusted suppliers who can provide equipment with the necessary technical characteristics, such as:

- High performance and optimal working flow.

- Energy efficient engines and control systems.

- IP55 protection and isolation class H for work in difficult conditions.

6.3 Careful installation and installation

The correct installation of the fan plays a key role in its long -term work:

- Provide the accurate alignment of the fan with the pipeline system.

- Use high -quality fasteners and sealants to prevent leaks.

- Test the system after installation to verify compliance with the calculated parameters.

6.4 Integration of modern technologies

The introduction of monitoring and automation systems allows you to track the fan parameters in real time, quickly identify deviations and conduct preventive maintenance. The use of such technologies helps to reduce energy consumption and increase the reliability of the system.

6.5 staff training

Regular training and advanced training of technical personnel for the operation and maintenance of ventilation equipment allows you to minimize the risk of errors and increase the service life of the system.

7. Economic efficiency and long -term benefits

7.1 Reduction of electricity costs

The optimized ventilation system using high -quality fans can significantly reduce energy costs by increasing energy efficiency and reducing pressure losses in pipelines.

7.2 Improving safety and working conditions

Effective ventilation improves the microclimate in production, reduces the risk of accumulating harmful gases and dust, which significantly increases the safety of employees and ensures stable equipment.

7.3 Return of investment http://www.hengdingfan.ru

Investments in high -quality ventilation equipment are paid off by reducing operating costs, reducing the number of accidents and increasing productivity. Long -term operation of the optimized ventilation system contributes to significant saving of funds.

8. Conclusion

The selection and installation of radial centrifugal fans, taking into account the length of the pipelines and the specifics of your plant are the key to the effective, reliable and economical operation of the ventilation system. A thorough analysis of operating conditions, the correct calculation of the parameters, the selection of high -quality equipment (with the protection of IP55 and the insulation class H) and professional installation provide optimal distribution of air flow, reduction of energy consumption and increase in safety at the enterprise.

Practical examples from Russia, Kazakhstan and Europe confirm that competent design of ventilation systems allows us to achieve significant saving and increasing productivity. Modern technologies for monitoring, automation and regular maintenance are key elements that contribute to the long -term stability of the system.

Investments in high -quality fans not only pay off by reducing electricity costs, but also create favorable conditions for the work of personnel, increasing the overall efficiency and safety of production. It is recommended to cooperate with trusted suppliers and attract qualified specialists to ensure the successful operation of the ventilation system.