Are old fans working slowly? Here's how to serve your ventilation system to reduce energy consumption by 20% and save costs

2025-03-13

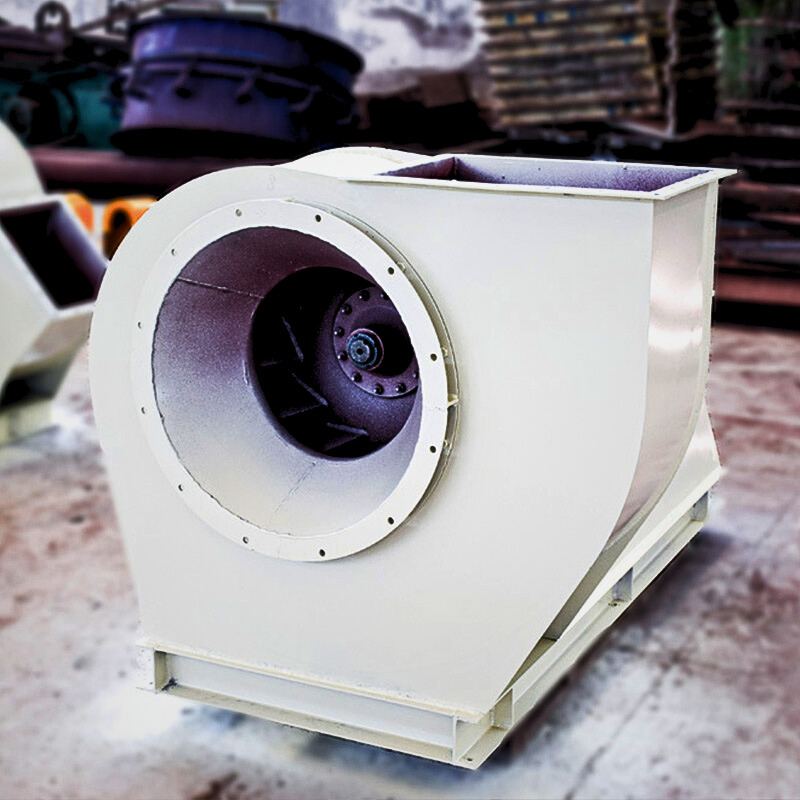

In modern industrial and commercial facilities, the ventilation system plays a key role in ensuring comfort and safety. However, over time, even high-quality fans begin to lose their effectiveness due to wear, accumulation of pollution and obsolete of technology. If timely maintenance is not carried out, old fans can work slowly, which leads to a significant increase in energy consumption and operating costs. In this article, we will examine in detail how to properly serve and maintain your ventilation system in order to reduce energy costs by 20% and save money.

1. The value of regular maintenance of ventilation systems

1.1 The effect of equipment wear http://www.hengdingfan.ru

Over time, any mechanical devices are susceptible to wear. Fans working in conditions of round -the -clock operation, especially in aggressive environments, lose their original performance. Bearing wear, dust accumulation on blades, lubrication leakage and corrosion - all these factors can lead to a decrease in the efficiency of fan operation.

1.2 Economic service efficiency

Regular maintenance allows you to identify and eliminate small malfunctions before they develop into serious breakdowns. Planned maintenance reduces the risk of unscheduled stops, which directly affects electricity saving and reducing repair costs. Investments in preventive maintenance are paid off by increasing the overall performance of the system and increasing the service life of the equipment.

1.3 Improving reliability and security

The effectively working ventilation system provides a stable flow of fresh air, removal of harmful gases and maintaining the optimal microclimate. This is especially important for industrial enterprises where insufficient ventilation can lead to overheating of equipment, worsening working conditions and even emergency situations. Regular service avoids such risks and ensure security at the workplace.

2. The main problems of old fans

2.1 Clouding of pollution http://www.hengdingfan.ru

Over time, dust and other pollution accumulate on the blades, inside the housing and on the filters of the fans. This leads to a decrease in performance, an increase in the resistance of the air flow and, as a result, increased energy consumption. Cleaning these components is an important part of regular maintenance.

2.2 wear of bearings and fasteners

Mechanical components, such as bearings and screws, play a critical role in the stable operation of the fans. Bearing wear can lead to uneven rotation, increased vibrations and noise, which negatively affects the overall efficiency of the system. It is especially important to pay attention to the quality of fasteners: the use of high -strength screws instead of ordinary ones can significantly increase the service life of the equipment.

2.3 outdated control technologies

Many old fans are not equipped with modern management systems, such as inverter management. This leads to ineffective operation of the device, increased electricity consumption and the impossibility of adaptation to changing operating conditions.

2.4 Corrosion and mechanical damage

In an aggressive environment, especially with a high level of humidity and the presence of chemicals, the metal components of the fans can be corroded. This reduces the strength and durability of the equipment, increasing the risk of its breakdown.

3. Recommendations for maintenance and modernization of fans

3.1 regular cleaning and technical examinations

-

Periodic cleaning:

Regular cleaning of blades, filters and internal components of the fan helps to maintain its aerodynamic characteristics. It is recommended to clean at least once a month, especially in dusty conditions. -

Planned technical examinations:

Planned examinations of all mechanical and electrical components of the fan system allow you to identify small malfunctions at an early stage. This includes a check of bearings, fasteners and lubrication systems.

3.2 replacement of worn parts

-

Bearings and screws:

Particular attention should be paid to the condition of the bearings. If signs of wear are found, they must be replaced in a timely manner. In addition, the use of high -strength screws instead of regular provides a more reliable fastening of the components and prevents vibrations. -

Filters:

Filters that collect dust and pollution should be regularly cleaned or replaced. This is especially important for systems working in conditions of increased ardor or air pollution.

3.3 modernization of the control system

-

Inverter management:

The introduction of inverter control systems allows us to optimize the fan operation, adjusting its speed depending on the current load. This not only reduces power consumption, but also increases the life of the equipment. -

Monitoring systems:

Modern sensors and monitoring systems allow in real time to track the fan parameters: temperature, pressure, rotation and vibration. Information obtained in real time helps to quickly identify deviations and conduct preventive measures.

3.4 Using high -quality lubricants

The correct lubrication of bearings and other moving parts reduces friction and wear. It is recommended to use high -quality lubricants corresponding to operating conditions. Regular lubrication replacement is a key element of preventive maintenance, which avoids overheating and reducing the risk of breakdowns.

3.5 staff training and process optimization

Qualified personnel plays an important role in maintaining the effective operation of the ventilation system. Regular training on modern methods of maintenance and operation of equipment helps to reduce the number of errors and increase the overall reliability of the system. It is also important to introduce standardized procedures for maintenance and repair, which allows you to optimize work processes.

4. Examples of successful projects

4.1 Example of modernization at an industrial enterprise in Russia

At one of the plants in Russia, the old fans with the installation of inverter control systems and replacement of worn bearings with high -strength models was modernized. Thanks to these measures, it was possible to reduce energy consumption by 20% and increase the total volume of the moved air by 15%. The result was an increase in performance and improving working conditions for employees.

4.2 An example of updating the ventilation system in the mine of Kazakhstan

In one of the mines of Kazakhstan, where operating conditions were especially complicated due to high humidity and dust load, a comprehensive modernization of the ventilation system was carried out. As part of the project, old fans were replaced, modern monitoring systems were installed and bearings with high -strength screws were replaced. These measures made it possible to reduce energy consumption by 20%, increase the reliability of the system and significantly reduce the risk of emergency situations.

4.3 An example of optimizing the cooling system in a shopping center in Europe

In one of the large shopping centers in Europe, the ventilation system was optimized in order to reduce energy consumption and increase comfort for visitors. The introduction of energy -efficient fans, modernization of the management system and regular maintenance allowed to reduce energy consumption by 20% and reduce noise, which contributed to the creation of a favorable microclimate and reducing operational costs.

5. Economic efficiency and return on investment

5.1 Reducing electricity costs

Optimization of the operation of the ventilation system due to the modernization of old fans can significantly reduce energy costs. Energy efficient models with inverter management work optimally in a variable load, which reduces electricity consumption and reduces operating costs.

5.2 Improving the service life of equipment

Regular maintenance, timely replacement of worn parts and modernization of control systems can significantly increase the service life of ventilation equipment. This reduces the cost of repair and replacement of equipment, increasing the economic efficiency of the enterprise.

5.3 Improving performance and security

Effective ventilation provides a stable flow of fresh air and removal of harmful gases, which significantly increases the safety and working conditions. Improved working conditions contribute to increasing productivity and reducing the risk of accidents, which positively affects the overall profitability of the enterprise.

6. Recommendations for optimizing ventilation systems

6.1 Conducting a detailed analysis of the condition of the equipment

Before modernization, it is necessary to conduct a thorough audit of the ventilation system, identify weaknesses, make measurements and calculations according to key parameters. This will determine what measures of service and modernization will be most beneficial.

6.2 Implementation of modern monitoring technologies

Installation of temperature sensors, pressure and vibrations will quickly monitor the condition of ventilation equipment. Modern monitoring systems help identify potential problems and carry out preventive measures in a timely manner.

6.3 staff training

Investments in the training of technical personnel contribute to the proper operation and maintenance of equipment. Qualified specialists will be able to carry out the necessary work in a timely manner, which will reduce the risk of accidents and increase the overall efficiency of the system.

6.4 Cooperation with trusted suppliers

The choice of reliable suppliers guarantees high quality equipment and provides the opportunity to obtain qualified technical support. This allows not only to increase the efficiency of the system, but also to reduce operating costs through the use of modern, energy -efficient technologies.

7. Conclusion http://www.hengdingfan.ru

Old fans can significantly lose efficiency over time, which leads to an increase in energy consumption and an increase in operating costs. However, proper maintenance, regular replacement of worn parts and modernization of the management system allow reducing energy costs to 20% and significantly extend the service life of the equipment.

This article discusses the main problems of old fans, the recommendations for their maintenance are given and examples of successful projects are given, where an integrated approach to the modernization of ventilation systems brought significant savings in funds and increasing productivity. Investments in energy -efficient equipment and the introduction of modern monitoring technologies are key factors to achieve optimal operation of the ventilation system.

Maintaining the ventilation system in perfect condition not only improves working conditions and increases safety at the enterprise, but also promotes significant energy savings, reduce costs and increase the overall profitability of business. It is important to remember that regular maintenance, competent selection of components and modernization of equipment are strategic measures that allow ensuring long -term stable operation of the ventilation system and return the investment by reducing operating costs.