【Technical breakthrough】 New generation of highly effective energy -saving axial fans has been released, which helps reduce energy consumption by 30% in industry

2025-03-15

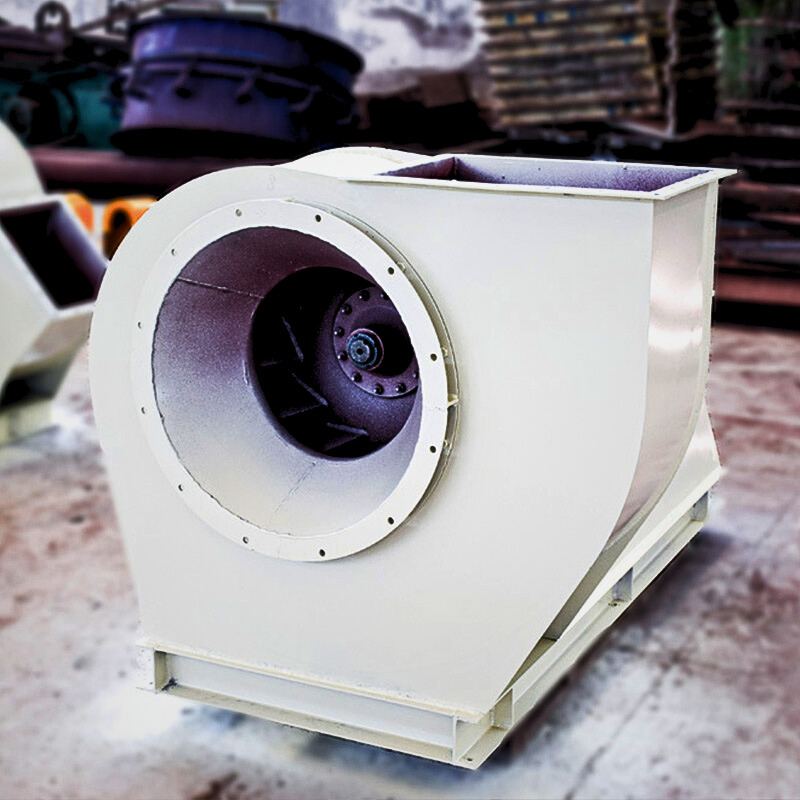

In the context of constantly growing requirements for energy efficiency and reducing operating costs, innovative solutions in the field of ventilation play a decisive role for industrial enterprises. Modern axial fans have long ceased to be standard devices - now they are equipped with advanced technologies that can significantly increase the efficiency, reduce energy consumption and improve operational characteristics. Today we are pleased to present a new generation of highly effective energy -saving axial fans that can reduce energy consumption to 30% due to the use of innovative aerodynamic solutions, optimized structures and modern management methods. This novelty opens up new opportunities for industrial ventilation systems and is becoming a strategic solution for enterprises striving for environmental and economic efficiency.

1. Technological innovation and key features

1.1 Innovative aerodynamic decisions

The new generation of axial fans is developed using the latest methods of modeling and computing hydrodynamics (CFD). This allowed engineers to optimize the shape of the blades, their angle of inclination and the distribution of mass, which significantly improves aerodynamic characteristics. Thanks to this approach, it is achieved:

- The maximum air flow at minimal energy costs.

- Reducing turbulence and air flow resistance.

- The optimal pressure distribution, which increases the efficiency of the fan in systems with long pipelines.

1.2 Optimized design and materials

To increase durability and reliability, the new generation of fans is made of high -quality materials. The use of modern alloys, such as stainless steel and aluminum composites, provides not only strength and resistance to corrosion, but also reduces the weight of the structure, which positively affects energy consumption. Particular attention is paid to:

- The fan impeller, whose design is optimized to ensure a stable air flow.

- The body, which is designed to protect internal components at extreme temperatures and aggressive environment.

- The use of highly effective electric motors that allow you to adjust the speed of rotation using inverter control.

1.3 intellectual management systems

Modern fans are equipped with intellectual monitoring and automatic control systems. Such systems allow:

- In real time, track the fan parameters (speed, pressure, temperature, noise level).

- Automatically adjust the operating mode depending on changes in operating conditions.

- To warn about possible deviations in the work and initiate preventive maintenance until serious malfunctions occur.

2. Advantages of the new fan generation

2.1 Reducing energy consumption

One of the most significant advantages of the new technology is to reduce energy consumption. The optimization of aerodynamics and the use of energy -efficient electric motors allow reducing electricity costs to 30%. This is especially important for large industrial enterprises, where energy costs make up a significant part of operational expenses.

2.2 Improving reliability and service life

Thanks to the improved design and the use of modern materials, the new generation of fans is highly reliable and durable. Reducing mechanical wear, reduction of vibrations and stable operation of all components of the system lead to reducing the cost of maintenance and repairs.

2.3 Improving operational characteristics

The optimized air flow, achieved due to the well -thought -out design of the blades, provides uniform distribution of air, which increases the overall efficiency of the ventilation system. This, in turn, helps to improve working conditions, reduce noise levels and create a comfortable microclimate at the facility.

2.4 Economic efficiency and environmental stability

Reducing energy consumption and increasing the productivity of ventilation systems directly affects the economic efficiency of the enterprise. Moreover, a decrease in energy consumption helps to reduce carbon dioxide emissions, which is an important aspect of environmental stability. Investments in modern fans pay off by reducing operating costs and increasing the competitiveness of the enterprise.

3. Fields of application of new generation of axial fans

3.1 Industrial production

At industrial enterprises, ventilation plays a key role in cooling equipment and maintaining optimal working conditions. The new generation of fans allows you to effectively remove excess heat, reducing the risk of overheating of the equipment and extending its service life. This is especially true for:

- Plants for the production of steel and aluminum.

- Chemical and petrochemical plants.

- Production workshops with intensive technological load.

3.2 ventilation of tunnels and underground communications

Effective ventilation of tunnels is an important element of security in underground structures. New fans capable of working in conditions of long pipelines with high static pressure guarantee a constant influx of fresh air and removal of harmful gases. This reduces the risk of emergency situations and provides comfort for users of underground transport systems.

3.3 commercial and office buildings

In modern shopping centers, office buildings and residential complexes, providing high -quality ventilation is critical of creating a comfortable microclimate. New fans with optimized parameters provide:

- Uniform air distribution.

- Reducing the noise level.

- Energy efficient work, which reduces operating costs and increases comfort for people.

3.4 Energy sector

At thermal power plants and other energy facilities, ventilation provides not only cooling equipment, but also support for the optimal temperature regime in workshops and residential areas. A new generation of fans helps to reduce electricity costs and increase the overall efficiency of cooling systems.

4. Examples of successful projects

4.1 Example from Russia

In one of the large industrial enterprises in Russia, the ventilation system was modernized using the new generation of axial fans. Due to the optimization of the design of the blades, the integration of intellectual control systems and increased energy efficiency, it was possible to reduce energy consumption by 30%, and the total volume of the movement of the movement is increased by 20%. This led to a significant decrease in operational costs and increase the reliability of the equipment.

4.2 Example from Kazakhstan

At a mine in Kazakhstan, the installation of a modern ventilation system with new fans allowed to ensure a stable flow of fresh air in conditions of complex pipelines and high humidity. The use of innovative technologies, such as inverter management and intellectual monitoring, contributed to a decrease in energy consumption and increasing the safety of the mine. Due to this, the risk of explosive gases accumulation was significantly reduced, and the system performance increased.

4.3 Example from Europe

In one of the large shopping centers in Europe, the ventilation system was optimized using the new axial fan generation. A thorough selection of parameters, including optimizing the shape of the blades and setting up the control system, made it possible to create uniform distribution of air, reduce noise level and reduce energy consumption. As a result, operating expenses were significantly reduced, and the comfort of visitors and employees was significantly increased.

5. Recommendations for the choice and implementation

5.1 Pre -analysis

Before the introduction of new equipment, it is important to conduct a detailed analysis of operating conditions:

- Determine the size of the premises and the length of the pipelines.

- Calculate the required volume of air and static pressure.

- Consider environmental features, such as temperature, humidity and level of pollution.

5.2 Cooperation with experts

It is recommended to work with experienced specialists and trusted suppliers of ventilation equipment. This will accurately calculate the parameters of the system, select the optimal fan model and provide high -quality installation.

5.3 Integration of modern technologies

The introduction of automatic control and monitoring systems is an important step to ensure stable operation of the system. Use sensors to control the temperature, pressure and noise level, as well as the inverter control system to regulate the fan speed, depending on the current conditions.

5.4 regular maintenance

Planned equipment maintenance is the key to its long -term and efficient operation. Regular cleaning, checking and replacing worn parts will help maintain optimal operation parameters and prevent emergency situations.

6. Economic efficiency and sustainability

6.1 Reduced energy cost

Optimization of the operation of the ventilation system using the new generation of axial fans can significantly reduce energy consumption. The effective use of electricity leads to a decrease in operating costs and an increase in the economic efficiency of the enterprise.

6.2 Safety increase

Effective ventilation significantly reduces the risk of accumulation of explosive gases and pollutants, which directly affects the safety of personnel and production processes. Reliable equipment and timely maintenance increase the level of safety at the facility.

6.3 Return of investment

Investments in modern, highly effective fans pay off by reducing electricity costs, reducing the number of accidents and increasing the overall system performance. An integrated approach to ventilation optimization contributes to significant saving and long -term production stability.

7. Conclusion http://www.hengdingfan.ru

The new generation of highly effective energy -saving axial fans is a real technological breakthrough in the field of ventilation. Thanks to innovative aerodynamic solutions, optimized design, modern control and automation systems, these fans can reduce energy consumption to 30% and significantly increase the efficiency of ventilation systems. The correct choice, professional installation and regular maintenance are key factors that contribute to the successful operation of equipment.

Examples of successful projects from Russia, Kazakhstan and Europe confirm that investments in high -quality ventilation systems pay off by increasing performance, reducing operational costs and ensuring security at the enterprise. To achieve the best results, it is necessary to conduct a thorough analysis of operating conditions, work with experienced specialists and implement modern technologies, which will create an optimal ventilation system that meets all the requirements of modern production.