How to choose the right coating for the fan blades? In fact, everything comes down to several main types! Determine this to significantly save money

2025-03-14

In modern industrial and commercial ventilation systems, fan blades play a key role in ensuring stable air flow, effective cooling and general maintenance of optimal microclimate. However, even the most thoughtful design of the fan can lose its operational qualities if the surface of the blades is not protected from aggressive environmental impact. Coating blades is an important technological process that helps to increase durability, efficiency and reduce equipment maintenance costs.http://www.hengdingfan.ru

In this article, we will consider how to choose the correct coating for the fan blades, what types of coatings exist, their main advantages and disadvantages, as well as recommendations on optimal use. Having mastered this knowledge, you can not only increase the efficiency of ventilation equipment, but also significantly save money on its operation.

1. The value of the fan blades

1.1 protection against corrosion and wearhttp://www.hengdingfan.ru

The fan blades are exposed to many negative factors, such as humidity, chemicals, dust and mechanical wear. The correct coating protects the surface of the blades from corrosion, prevents the aggressive effect of the environment and significantly increases the life of the device. This is especially important for ventilation systems operated in aggressive industrial conditions, where the stability and reliability of equipment are critical.

1.2 Improving aerodynamic characteristics

The coating of the blades can improve the aerodynamics of the fan, reducing friction between the air and the surface of the blades. This leads to a more efficient movement of the air flow, a decrease in resistance and, as a result, a decrease in energy consumption. The optimized coating allows you to achieve maximum fan performance with minimal electricity consumption.

1.3 noise decreasehttp://www.hengdingfan.ru

The accumulation of pollution and the wear of the blades can cause an increase in the noise level during the fan. High -quality coating helps to reduce vibrations and reduce noise, which is especially important for objects where a low level of sound pollution is required, for example, in office buildings, shopping centers and residential complexes.

2. The main types of fan blades

The market presents several main types of fan blades, each of which has its own characteristics, advantages and restrictions. Consider the main types:

2.1 powder coating

Description:

The powder coating is the application of dry powder, which is then baked at high temperature, forming a strong, resistant to corrosion and wear of the coating.

Advantages:

- Great resistance to corrosion.

- High mechanical strength.

- The environmental friendliness of the process (lack of solvents).

Flaws:

- Limited color scheme.

- Problems are possible when applying to complex forms.

2.2 liquid paintwork

Description:

Liquid coatings, such as enamel and polyurethane, are applied by spraying or dipping. After drying, a smooth and uniform film that protects the surface of the blades is formed.

Advantages:

- A wide selection of colors and finish effects.

- Good adhesion to various materials.

- Relatively low cost.

Flaws:

- It is less resistant to mechanical damage compared to powder coating.

- It may require additional protection against ultraviolet rays.

2.3 Polyurethane -based coatings

Description:

Polyurethane coatings are characterized by high elasticity and resistance to wear, which makes them popular for use in conditions of mechanical loads.

Advantages:

- High wear resistance.

- Resistance to chemical influences.

- Good adhesion and elasticity.

Flaws:

- Higher cost compared to traditional paintwork.

- Limited resistance to high temperatures.

2.4 Epoxy coatings

Description:

Epoxy coatings are known for their high strength and resistance to corrosion. They are used in industrial conditions, where durable protection against aggressive environment is required.

Advantages:

- High chemical resistance.

- Great adhesion and strength.

- The durability of the coating.

Flaws:

- Difficulty in applying (require thoroughly preparation of the surface).

- Can be sensitive to ultraviolet radiation.

3. How to choose the right coating for fan blades

3.1 Evaluation of operating conditions

Before choosing a coating, it is important to analyze the conditions in which the fan will be operated:

- The aggressiveness of the environment:In conditions of high humidity, salt water or chemical agents, it is preferable to use powder or epoxy coating.

- Mechanical loads:If the fan is exposed to strong vibrations and mechanical influences, it is better to choose polyurethane -based coatings.

- Requirements for aesthetics:For objects where the appearance is important, liquid paints and varnishes with a wide selection of colors can be selected.

3.2 Analysis of technical characteristics

When choosing a coating, you should take into account:

- Corrosion resistance:The higher the aggressiveness of the environment, the higher the corrosion resistance of the coating should be.

- Wear resistance:The coating should withstand a long period of operation without a significant deterioration in protective properties.

- Temperature mode:Some coatings have a limited temperature range, therefore, for high -temperature conditions, it is necessary to choose materials with increased heat resistance.

- Price:Economic efficiency also plays a role - the cost of the coating must correspond to the project budget and pay off by reducing the costs of maintenance and replacement of equipment.

3.3 Practical recommendations

- Testing:It is recommended to conduct laboratory and field tests of the selected coating in order to make sure its suitability for specific operating conditions.

- Compare manufacturers' offers:Contact several suppliers, study the technical specifications and reviews to choose the best solution.

- Consider the guarantee obligations:Pay attention to the warranty conditions provided by the manufacturer, which indicates trust in the quality of the product.

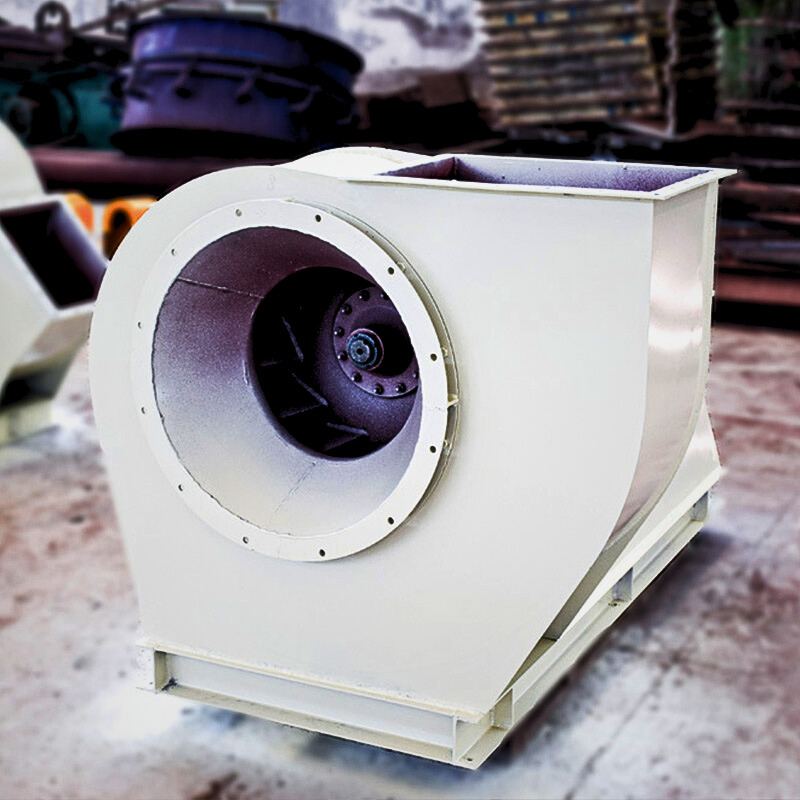

4. The use of radial centrifugal fans with an optimized coating of blades

4.1 Industrial use

In industrial conditions, where ventilation plays a key role in cooling equipment and ensuring production safety, the choice of proper coating for blades is critical. Radial centrifugal fans with optimized coating provide:

- Resistance to aggressive environment:The use of epoxy or powder coatings allows you to protect the blades from corrosion and chemical exposure.

- Reducing service costs:The durable coating reduces the frequency of repairs and replacements, which positively affects operating costs.

- Improving efficiency:An optimized coating helps to improve aerodynamic characteristics, reducing energy consumption and noise level.

4.2 ventilation of mines and mines

In the conditions of mining industry, where the risk of corrosion and wear is especially high, the choice of proper coating for the blades is critical. Radial centrifugal fans equipped with strong and durable coatings allow:

- Prevent the accumulation of dust and harmful gases:Effective removal of pollutants is ensured due to the stable operation of the fan.

- Ensure safe working conditions:Reliable coating reduces the risk of equipment failure, which is critical to ensure the safety of miners.

- Extend the life of the equipment:High -quality coating protects the blades from mechanical damage and corrosion, increasing the fan service life.

4.3 Application in commercial and office buildings

For shopping centers, office and residential complexes, it is important not only to ensure effective ventilation, but also to maintain an aesthetic type of equipment. Liquid paint coatings allow you to achieve an attractive appearance, while providing protection against dust and moisture. Radial centrifugal fans with such coatings contribute to:

- Creating a comfortable microclimate:Uniform air distribution improves working conditions and increases the comfort of visitors.

- Reducing the noise level:Optimization of aerodynamics due to the correct coating helps to reduce vibrations and noise.

- Energy efficiency:Reducing energy losses reduces operating costs.

5. Practical examples

5.1 Example from Russia

At one of the industrial enterprises in Russia, a ventilation system was modernized using radial centrifugal fans equipped with powder blades. The tests showed that the chosen coating ensured high resistance to corrosion, reduced the noise level and increased the total volume of the moved air by 20%, which led to significant power saving and reducing the cost of maintenance.

5.2 Example from Kazakhstan

In a mine in Kazakhstan, a ventilation system was introduced, where fans with blades covered with epoxy material were used. This made it possible to ensure stable work in an aggressive environment with a high level of humidity and dust. Thanks to reliable protection, the ventilation system worked without failures, which significantly increased the safety of the mine and reduced the risk of emergency situations.

5.3 Example from Europe

In one of the large shopping centers in Europe, a ventilation system used fans with blades covered with high -quality paintwork materials. This provided not only the effective movement of air, but also the aesthetic appearance of the equipment. The result was the creation of a comfortable microclimate, a decrease in the level of noise and energy consumption, which positively affected the satisfaction of visitors and the economic efficiency of the building.

6. Recommendations for choosing a fan blades

6.1 Assessment of operating conditions

Before choosing a coating for blades, it is necessary to carefully analyze the conditions in which the fan will be operated:

- Chemical aggressiveness of the environment.

- Temperature and humidity.

- Mechanical loads and vibration level.

- Aesthetic requirements for commercial objects.

6.2 Comparison of various types of coatings

The main types of coatings for the blades include:

- Powder coating:It is characterized by high strength and resistance to corrosion, ideal for aggressive conditions.

- Liquid paintwork:Provide a wide selection of colors and finish effects, suitable for objects where aesthetics are important.

- Epoxy coatings:They have high chemical resistance and strength, which makes them optimal for mines and industrial enterprises.

- Polyurethane coatings:They are characterized by high elasticity and wear resistance, which is useful with high mechanical stress.

6.3 Practical recommendations

- Carry out laboratory testing of the selected coating on samples to evaluate its resistance to corrosion and wear.

- Contact specialists for calculating optimal parameters, taking into account the features of your object.

- Consider the operating costs: sometimes more expensive coatings pay off by reducing the costs of maintenance and extending the service life of equipment.

7. Economic efficiency

7.1 Reducing operating costs

The choice of proper coating can significantly reduce the cost of maintenance, since high -quality coating protects the blades from corrosion and mechanical damage, reducing the need for frequent repairs and replacements.

7.2 Increased energy efficiency

The optimized coating helps to improve the aerodynamic characteristics of the fan, which leads to a decrease in energy consumption and increased system performance. This is especially important for large industrial facilities, where each percentage of energy savings is of great importance.

7.3 Long -term investment return

Investments in high -quality coating are paid off by increasing the life of the equipment and reducing general operating costs. The correct choice and regular maintenance of ventilation systems contribute to increasing the overall economic efficiency of the enterprise.

8. Conclusionhttp://www.hengdingfan.ru

The choice of proper coating for the fan blades is a strategic step that affects the durability, efficiency and economic efficiency of the entire ventilation system. The correct combination of technologies and materials based on a thorough analysis of operating conditions allows you to achieve maximum performance and significant energy savings.

The main types of coatings considered in this article - powder, liquid varnish, epoxy and polyurethane - are the main options that can be selected depending on the specifics of your object. Having mastered this knowledge, you can make a reasonable choice that will help not only ensure the reliable operation of the equipment, but also significantly reduce operating costs.

Practical examples from Russia, Kazakhstan and Europe demonstrate that competent design and optimization of the operation of ventilation systems, including the choice of coating for blades, pay off by increasing safety, energy efficiency and durability of equipment. It is recommended to cooperate with trusted suppliers, carry out detailed calculations and implement modern monitoring systems to control operation parameters, which will achieve the best results and ensure the long -term stability of the ventilation system.