How to choose the most suitable channel fan to save money

2025-03-11

Effective ventilation plays a key role in ensuring comfortable and safe conditions in various facilities - from industrial enterprises to office buildings and shopping centers. The duct fans, as the main link in ventilation systems, allow you to provide the necessary air exchange, remove contaminated air and maintain the optimal microclimate. At the same time, the correct choice of the fan significantly affects not only the technical efficiency of the system, but also the economic component - the correct equipment can significantly reduce electricity costs, maintenance and repair.

In this article, we will consider how to choose the right channel fan that will comply with your specific operating conditions and help save money. We will dwell in detail on the technical parameters, methods of optimizing the system, as well as give practical recommendations and examples of successful projects confirming the economic efficiency of the competent choice of the fan. http://www.hengdingfan.ru

1.

1.1 The role of ventilation in modern construction and industry

Ventilation systems are an integral part of the infrastructure of any modern object. Their main tasks are:

- Ensuring the flow of fresh air and removing the contaminated,

- Maintaining the optimal microclimate (temperature, humidity),

- Equipment cooling and preventing overheating,

- Creation of safe working conditions due to the timely removal of harmful gases and dust.

Effective ventilation helps to improve working conditions, increase productivity and, as a result, saving funds by reducing electricity costs and repairing equipment.

1.2 Economic benefit from the right choice

The correct choice of the fan allows:

- Reduce energy consumption by optimizing the operation of the system,

- Reduce maintenance and repair costs,

- Extend the service life of equipment thanks to high -quality installation and regular maintenance,

- Create conditions for stable work, which reduces the risk of emergency situations and downtime of production processes.

Thus, investments in high -quality ventilation equipment are paid off due to long -term savings and increased performance.

2. Technical parameters affecting the choice of fan

When choosing a channel fan, it is necessary to take into account several key technical parameters:

2.1 Air volume (q, m³/min)

The volume of air that the fan is able to move is one of the main indicators. It depends on the size of the premises or the air duct system and determines the effectiveness of the air exchange. For large objects, a fan with a high value of Q is required, which allows you to provide sufficient air circulation and maintain optimal climatic conditions.

2.2 working pressure (PA)

Working pressure is the parameter necessary to overcome the resistance of the pipeline system. Long or winding pipelines create additional resistance, and the fan must have sufficient power to ensure a stable flow of air. The exact calculations of static pressure allow you to choose a device that can work effectively even with high resistance.

2.3 electric motor power (kW)

The power of the electric motor determines how much energy the fan consumes and how steadily it works with given loads. Highly efficient engines with modern technologies, such as inverter control, make it possible to optimize electricity consumption and reduce operating costs.

2.4 rotation speed (R/min)

The speed of rotation of the blades affects the dynamics of the air flow. Higher speed allows you to create a powerful stream, but it can lead to an increase in energy consumption and noise level. Optimization of this parameter is an important stage when choosing a fan.

2.5 diameter of the air duct (mm)

The diameter of the duct directly affects the resistance of the system and, accordingly, the required operating pressure of the fan. The correct combination of the diameter and length of the pipelines allows minimizing pressure losses and ensuring the effective distribution of air.

2.6 additional parameters

No less important are parameters such as the noise level, protection against dust and moisture (for example, IP55) and the class of electrical insulation (for example, class H). These characteristics provide reliable operation of the equipment in difficult conditions and contribute to a decrease in operating costs.

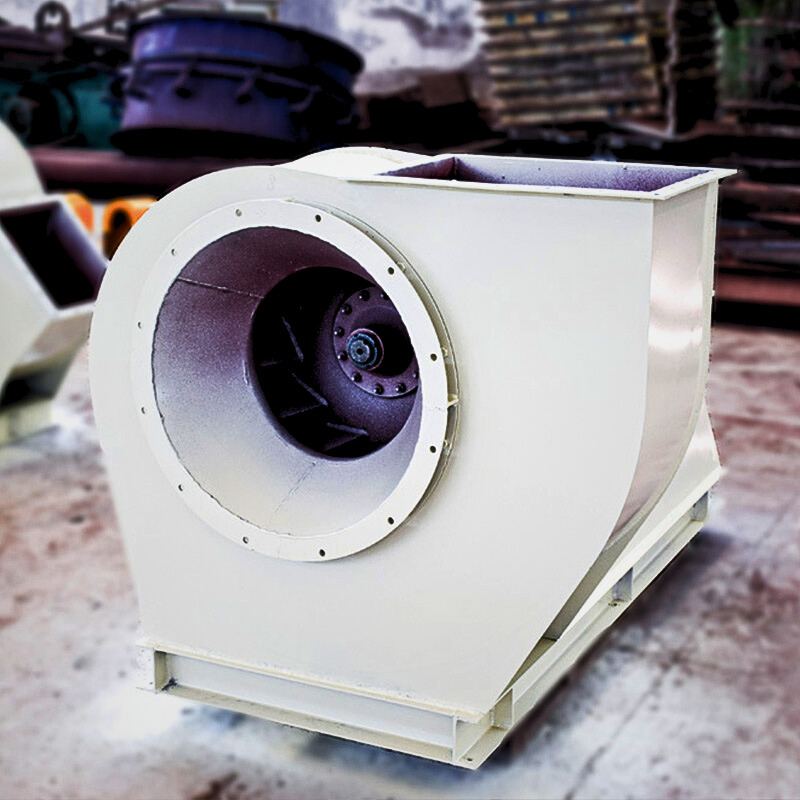

3. The use of radial centrifugal fans

3.1 industrial use

Radial centrifugal fans are widely used for ventilation of production workshops, warehouses and other industrial premises. Their high productivity and the ability to create significant static pressure allow you to effectively cool the equipment and ensure the removal of contaminated air. Energy efficient models help reduce electricity costs and increase the overall efficiency of the system.

3.2 ventilation of tunnels and underground structures

In the ventilation systems of tunnels and mines, where it is required to move the air over long distances, radial centrifugal fans play a decisive role. The correctly selected fan provides a stable tributary of fresh air, removal of harmful gases and maintaining the optimal level of oxygen. This is especially important for ensuring the safety of workers in underground conditions.

3.3 commercial and office buildings

In shopping centers, office buildings and other commercial facilities, not only the efficiency of ventilation is important, but also the noise level. Radial centrifugal fans with optimized parameters allow you to create a comfortable microclimate, reduce noise and provide stable air distribution, which positively affects the working environment and user satisfaction.

4. Practical recommendations for choosing a canal fan http://www.hengdingfan.ru

4.1 Analysis of operating conditions

Before choosing a fan, it is important to conduct a thorough analysis of the conditions at the facility:

- Measure the length, diameter and configuration of pipelines.

- Determine the required volume of air (m³/min) and static pressure (PA).

- Consider environmental features, such as temperature, humidity and air pollution level.

4.2 exact parameters calculations

For the choice of optimal equipment, it is necessary to calculate all technical parameters:

- Air volume (Q):It determines how much air must be moved to ensure effective ventilation.

- Working pressure (PA):Allows you to overcome the resistance of the pipeline system.

- Engine power (kW):Provides the necessary productivity with optimal energy consumption.

- Rotation speed (R/min):Affects the dynamics of air flow and noise level.

4.3 Selecting equipment with IP55 protection and insulation class H

When choosing a fan for difficult operating conditions, be sure to pay attention to the protection of the device:

- IP55 protectionIt guarantees that the fan is resistant to dust and water jets, which is especially important for industrial facilities.

- Isolating class hIt means that the electric motor is able to operate at high temperatures, ensuring the durability and stability of the work even in extreme conditions.

4.4 Cooperation with reliable suppliers

The choice of quality equipment depends on the supplier. Work with trusted manufacturers who provide full technical documentation, quality certificates and warranty services. This will help to avoid problems in the future and reduce operating costs.

4.5 Integration with monitoring systems

Modern monitoring systems allow you to track the parameters of the fan in real time (temperature, pressure, vibration). This helps to timely detect deviations and conduct preventive maintenance, which significantly increases the reliability and efficiency of the system.

5. Examples of successful projects

5.1 Example from Russia

At one of the large industrial facilities in Russia, a ventilation system was implemented using radial centrifugal fans. Due to the exact calculations of the parameters of pipelines, the selection of equipment with the protection of IP55 and the insulation class H, as well as the professional installation, it was possible to increase the total volume of the movement by 25% and reduce energy consumption by 18%. This increased the safety and efficiency of the plant.

5.2 Example from Kazakhstan

In one of the mines of Kazakhstan, a ventilation system was introduced, designed to work in conditions of long and winding pipelines. The use of modern radial centrifugal fans, optimized by Q and PA parameters, made it possible to ensure a stable influx of fresh air, reducing the risk of explosive gases. This led to a significant reduction in emergency situations and a decrease in operational costs.

5.3 Example from Europe

In one of the shopping centers in Europe, the ventilation system using radial centrifugal fans was modernized. Optimized technical characteristics, including high performance and low noise, made it possible to create a comfortable microclimate in the building. The system is equipped with modern sensors that allow you to control the operation of equipment in real time, which has led to significant power saving and reducing service costs.

6. Economic efficiency and long -term benefits http://www.hengdingfan.ru

6.1 Reduction of electricity costs

An optimally selected fan, calculated taking into account all the parameters of the system, can significantly reduce energy consumption. Energy efficient models with inverting control adapt the speed of rotation to current loads, minimizing energy overrun and reducing operational costs.

6.2 increased performance and security

An effective ventilation system helps to improve working conditions and increase safety at the facility, preventing the accumulation of harmful gases and dust. This, in turn, leads to an increase in productivity and a decrease in the risk of emergency situations.

6.3 Return of investment

Investments in high -quality ventilation equipment are paid off by reducing energy consumption costs, reducing the number of accidents and increasing the overall performance of the enterprise. The correct choice, installation and regular maintenance of the ventilation system contribute to significant savings in a long -term basis.

7. Conclusion http://www.hengdingfan.ru

The choice of the most suitable duct fan, taking into account the length of the pipeline system, technical parameters and features of the facility, is a key factor for achieving saving and increasing the efficiency of work. A thorough analysis of operating conditions, accurate calculations, the choice of high -quality equipment with the protection of IP55 and the class of insulation H, as well as professional installation and regular maintenance - all these measures contribute to the creation of a reliable and energy -efficient ventilation system.

Examples of successful projects from Russia, Kazakhstan and Europe clearly demonstrate that competent design and optimization of the ventilation system pay off by reducing costs, increasing safety and increasing productivity. The integration of modern monitoring and automation technologies allows you to quickly respond to changes in the operation of equipment, which contributes to the long -term stability and economic efficiency of the enterprise.

To achieve the best results, it is recommended to cooperate with trusted suppliers, attract qualified specialists for calculations and installation, as well as introduce monitoring and automation systems, which will make it possible to optimize the operation of the ventilation system and ensure its long -term and efficient operation.